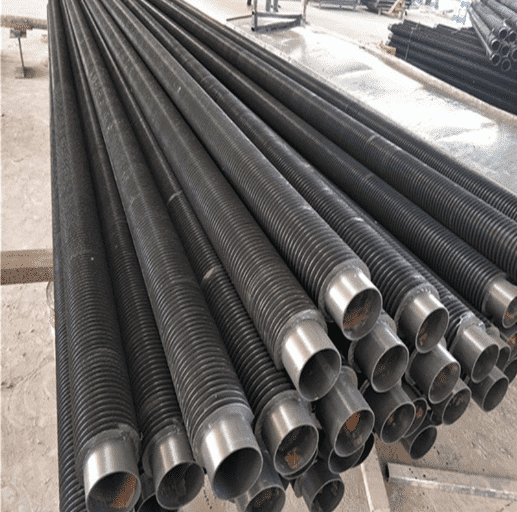

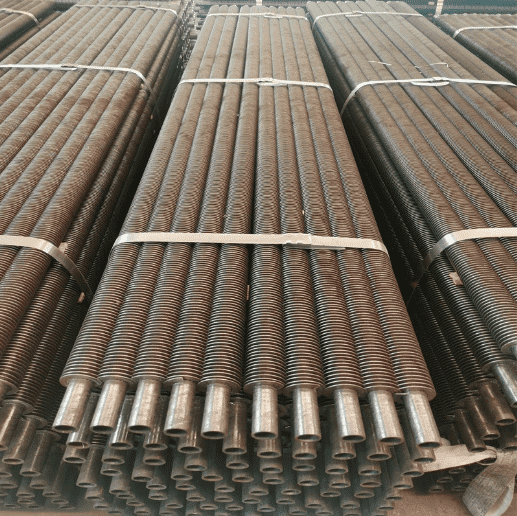

The stainless steel finned tube effectively increases the outer surface area or the internal standard area of the heat exchange tube during the working process, which can also achieve the purpose of improving the heat exchange efficiency of the stainless steel finned tube.

Finned tube is a wear-resistant, new and efficient heat exchange material. It is a high-efficiency and energy-saving heat exchange element during use.

The equipment mainly uses high-frequency power as the heat source to effectively heat the steel pipe and the steel strip at the same time. Heat it so that it fuses together into one piece.

Stainless steel finned tubes have the advantages of high heat exchange efficiency and large heat dissipation area when in use. The whole product has the advantages of long service life and wide temperature range during operation.

Stainless steel finned tubes have the advantages of high heat exchange efficiency and large heat dissipation area when in use. The whole product has the advantages of long service life and wide temperature range during operation.

The products are widely used in petrochemical, economizer, waste heat Recycling, greenhouses, power plant boilers, wood drying and other industrial fields.

The installation process of stainless steel finned tubes is very simple, and the connection points are economically reduced during operation.

Such equipment installation will become more economical and faster, and to a certain extent, the probability of water leakage at the connection will be reduced. , The product maintenance is simple, after the installation is completed, there is basically no need for maintenance.

The use efficiency of the finned tube is high. In the process of production, the steel tube and the fins are effectively wound and welded in full contact.

Its heat dissipation area is more than 8 times that of the light tube. The interior of the product will be smoother and the internal water flow will be smoother.

The resistance is relatively small, and the finned tube is to improve the heat exchange efficiency. Usually, fins are added to the surface of the heat exchange tube to increase the outer surface area (or inner surface area) of the heat exchange tube, so as to achieve the purpose of improving the heat exchange efficiency. A heat exchange tube.

L-type, double-L-type finned tubes, KL-type knurled finned tubes: working temperature: 230°C, using numerically controlled L-shaped finned tube machines to keep the bonding force of the tubes in the best state, and the trapezoidal cross-section formed by calendering is the same as The distribution of heat flux density is similar in size, on the basis of material saving, the thermal efficiency is greatly improved, and the contact thermal resistance caused by the inability to eliminate the gap between the finned tubes of the serial finned tubes is eliminated.

Features:

Using winding process, high production efficiency, uniform sheet distance, good heat transfer, high finning ratio, and the base tube can be protected from air erosion.

Stainless steel finned tubes are mainly used in air coolers and air heaters in petrochemical, electric power, papermaking, tobacco, building heating and other industries, and air heaters in spray drying systems for vegetable protein powder and starch in the food industry.