L/LL/KL finned tube

Fin Materials: Aluminum, Copper

Tube Materials: No limits

Fin Thickness: Min: 300 µ Max: 800µ

Contact Us:datangfintube@gmail.com

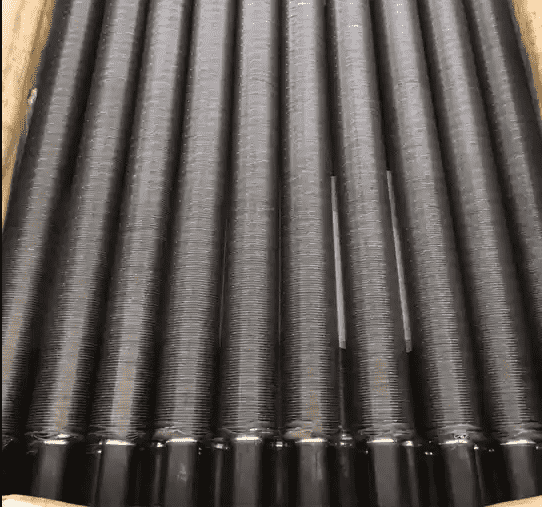

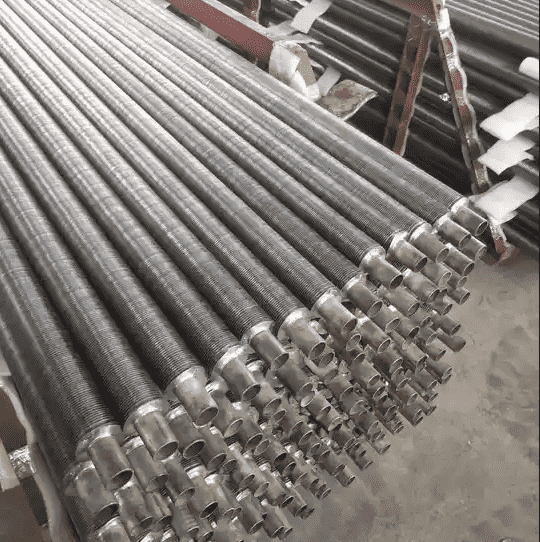

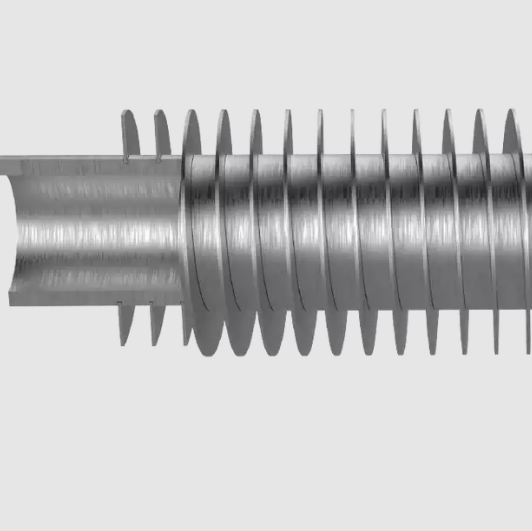

L type finned tube. Adopting the winding process, the production efficiency is high, uniform lamella distance , good heat transfer, high finization ratio, the base tube can be protected from air erosion.

The aluminum fin or copper fin is folded into an L shape and continuously spirally wound on the outer surface of the base tube under the action of tension.

Maximum working temperature-150°C (302°F), acceptable for atmospheric corrosion resistance, poor mechanical resistance. Commonly used heat sink materials are aluminum and copper.

LL type finned tube: Under the L-shaped foundation, the fin root completely covers the outer surface of the base tube; to some extent, this fin type guarantees better corrosion resistance.

Maximum working temperature-180°C (356°F), acceptable for atmospheric corrosion resistance, poor mechanical resistance. Commonly used heat sink materials are aluminum and copper

KL type finned tube: Before the fins are continuously wound on the surface of the steel pipe, the outer surface of the base pipe needs to undergo a knurling process; after the fins are wound, the root of the fin attached to the steel pipe will also be knurled to strengthen the steel pipe and Combination of fins.

For this reason, this fin type ensures better heat transfer characteristics under the fins of L and LL. Maximum working temperature-260°C (500°F), acceptable for atmospheric corrosion resistance, poor mechanical resistance. Commonly used heat sink materials are aluminum and copper

L Finned Tube is combined with two different materials

Core Tube: Carbon steel, stainless steel, copper

Fins: Aluminum, copper, steel

Features:

- Adopting winding process, high production efficiency

- Uniform fin pitch, good heat transfer performance

- Core tube is protected from air corrosion by base of fin