Finned tube heat exchanger are usually devices that convert thermal power and increase the area of heat. Many devices are used in our lives to achieve better living environment protection.

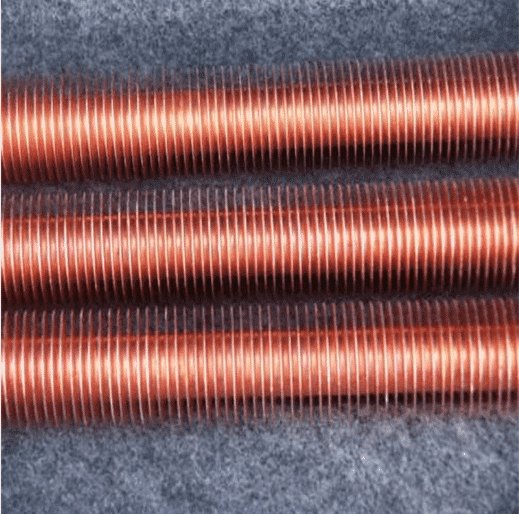

Finned heat pipes are the basic components of heat exchangers. Most of the heat exchange between hot and cold fluids is carried out through finned heat pipes, and a small part is carried out directly through partitions.

In a normal design, the heat transfer area of the finned heat pipe is about 67%-88% of the total heat transfer area of the heat exchanger. The connections between the finned tubes and the bulkhead are perfectly welded, so most of the heat is transferred to the finned tubes, which transfer the finned tubes to the cold fluid through the bulkhead.

The heat transfer of the finned heat pipe is not as direct as that of the partition, so the finned heat pipe has a secondary surface.

The secondary heat transfer surface is generally less efficient than the primary heat transfer surface. But what if these basic finned heat pipes didn’t have corrugated simple plate heat exchangers.

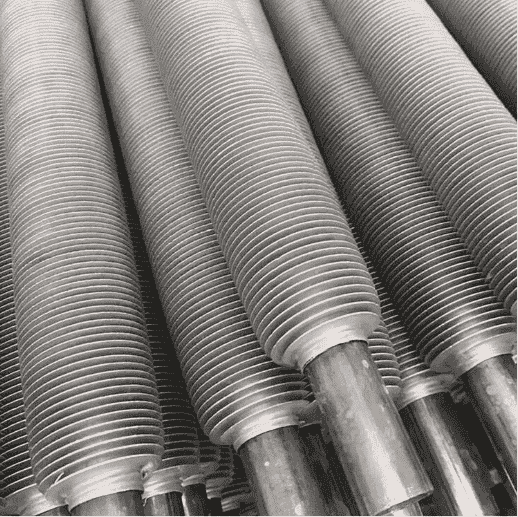

The finned heat pipe reduces the volume of the heat exchanger by more than 18% compared with the heat exchanger without fins. The finned heat pipe design can reduce its weight by 10% when its efficiency is 70% lower.

In addition to undertaking the main heat transfer task, the finned heat pipe also plays a role of reinforcement between the two compartments.

Although the material of the finned heat pipe and the separator is thin, the unit body formed by it has high strength and can bear relatively high pressure.

Finned cooling tubes have high anti-corrosion performance in use. During the normal use of items, the use of finned cooling tubes presents unique environmental advantages, adding many additional functions, and improving on the basis of the original facilities. Use functions to make the way of use in our life more convenient.

Abrasion resistance is also a notable feature of realizing finned heat pipes. When assembling components, the wear resistance of finned heat pipes always contributes to the durability of the equipment.

The necessary devices are not volatile in use. Finned heat pipes Improve the real recognition ability of the device, and have more practical advantages under environmental protection

The capabilities of finned heat pipes In many concepts, the use of finned tube is a fusion of emotions, effectively carrying a lot of skills in use, and it is also an effective method of use.

The finned tube heat exchanger is a new type of structure that uses steel pipes instead of steel plates, which is newly developed after a series of experimental studies on the basis of traditional heat exchangers.

It has the advantages of finned tube-plate heat exchangers, gets rid of many defects of plate heat exchangers, and has the advantages of high heat exchange efficiency, large pressure and pressure difference, and light weight.

Introduction to the characteristics of finned tube heat exchanger

Heat exchange equipment is commonly used in manufacturing industries such as electric energy, crude oil, and chemical plants, and in the daily life of residents.

The current heat transfer equipment includes shell and tube type, waterproof casing type, finned tube type and flat plate type, etc. Heat exchangers are divided according to the flow modes of thermal fluid mechanics and cold fluid mechanics, including forward flow, reverse flow, and countercurrent flow.

According to the flow method of hot and cold fluid mechanics, it can be divided into direct current, wave flow, swirl flow in pipe, flow around pipe, baffle flow, swirl flow and so on.

Among them, hot and cold fluids flow backwards from each other, and their swirling flow is an ideal method of heat exchangers, and finned tube plate heat exchangers belong to this category.

(1) The inner channel and the outer channel of the tube are both finned tube involute hydrodynamic channels, which can keep the heat transfer driven by the reverse direction and rotational fluidity of the primary medium and the secondary medium.

Compared with the finned tube plate heat exchanger, the finned tube heat exchanger has high heat exchange efficiency, less raw material consumption, compact structure, light weight, lighter weight, and high pressure bearing capacity. , the total heat transfer area is greatly increased, and the wall thickness is thinner.

(2) Applicable to situations where there is a large pressure difference between two safety passages. Due to the high-pressure bearing capacity of the finned tube magnetic coil, the high-pressure medium is introduced into the tube, and the low-pressure medium is introduced outside the tube.

(3) The equipment changes the spacing columns in the finned tube plate into spacing pieces, which saves raw materials and improves the heat conduction effect.

Compared with the current technology, the technical progress achieved by this equipment is that the two materials flow back and forth in separate finned tube channels to maintain heat exchange.

Compared with the finned tube plate heat exchanger, the finned tube heat exchanger The heat exchange area of the device is greatly increased, the heat exchange efficiency and energy utilization rate are improved, the wall thickness is reduced, the structure is compact, the volume is small and light, the pressure resistance is high, and the length of the safety channel is not increased.