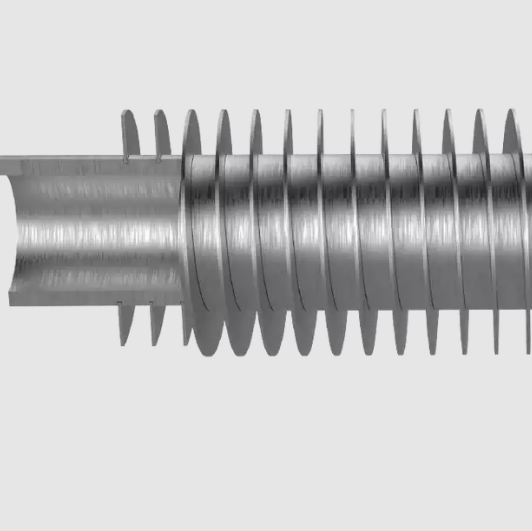

Finned tubes are heat exchangers composed of round tubes or light tubes, so how can the heat transfer of round tubes be improved?

One of the most effective methods is to use an extended surface on the outer surface of the tube, that is, the flue gas side, that is, to make a finned tube.

Assuming that the actual heat transfer area of the finned tube is several times the outer area of the original bare tube, although the heat transfer coefficient of the flue gas is still very low, the heat transfer effect reflected on the outer area of the bare tube will be greatly increased, so that the entire The heat transfer process is enhanced, and when the total heat transfer is constant, the metal consumption of the equipment is reduced and the economy is improved.

The application of finned tubes is introduced as follows:

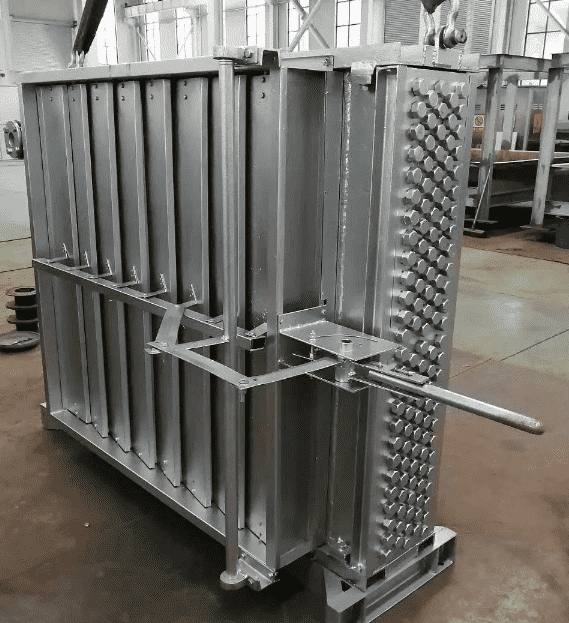

1. Heat pipe air preheater series

Application occasions: Absorb waste heat from flue gas and heat combustion-supporting air to reduce fuel consumption and improve combustion conditions, thereby achieving the purpose of energy saving; it can also absorb waste heat from flue gas to heat other gaseous media such as gas, etc.

2. Heat pipe economizer series

Application occasions: Absorb heat from the flue gas and use it to heat the feed water. The heated water can be returned to the boiler or used alone, so as to improve the energy utilization rate and achieve the purpose of energy saving.

3. Heat pipe waste heat boiler series

Application occasions: heat pipes are used as heat transfer elements to absorb higher temperature flue gas waste heat to generate steam, and the generated steam can be incorporated into the steam pipe network, and can also be used for power generation or other purposes.