Finned tubes are widely used in various industrial applications for their excellent heat transfer properties.

In the power generation industry, finned tubes play a critical role in increasing the efficiency of power station equipment.

In this article, we will discuss the application of finned tubes in power station equipment and their benefits.

Power stations are responsible for generating electricity through various means such as nuclear, thermal, or renewable sources.

In all these methods, heat transfer plays a vital role in the power generation process. Heat exchangers are an essential part of power station equipment that transfers heat from one fluid to another.

Finned tubes are commonly used in these heat exchangers to improve their efficiency.

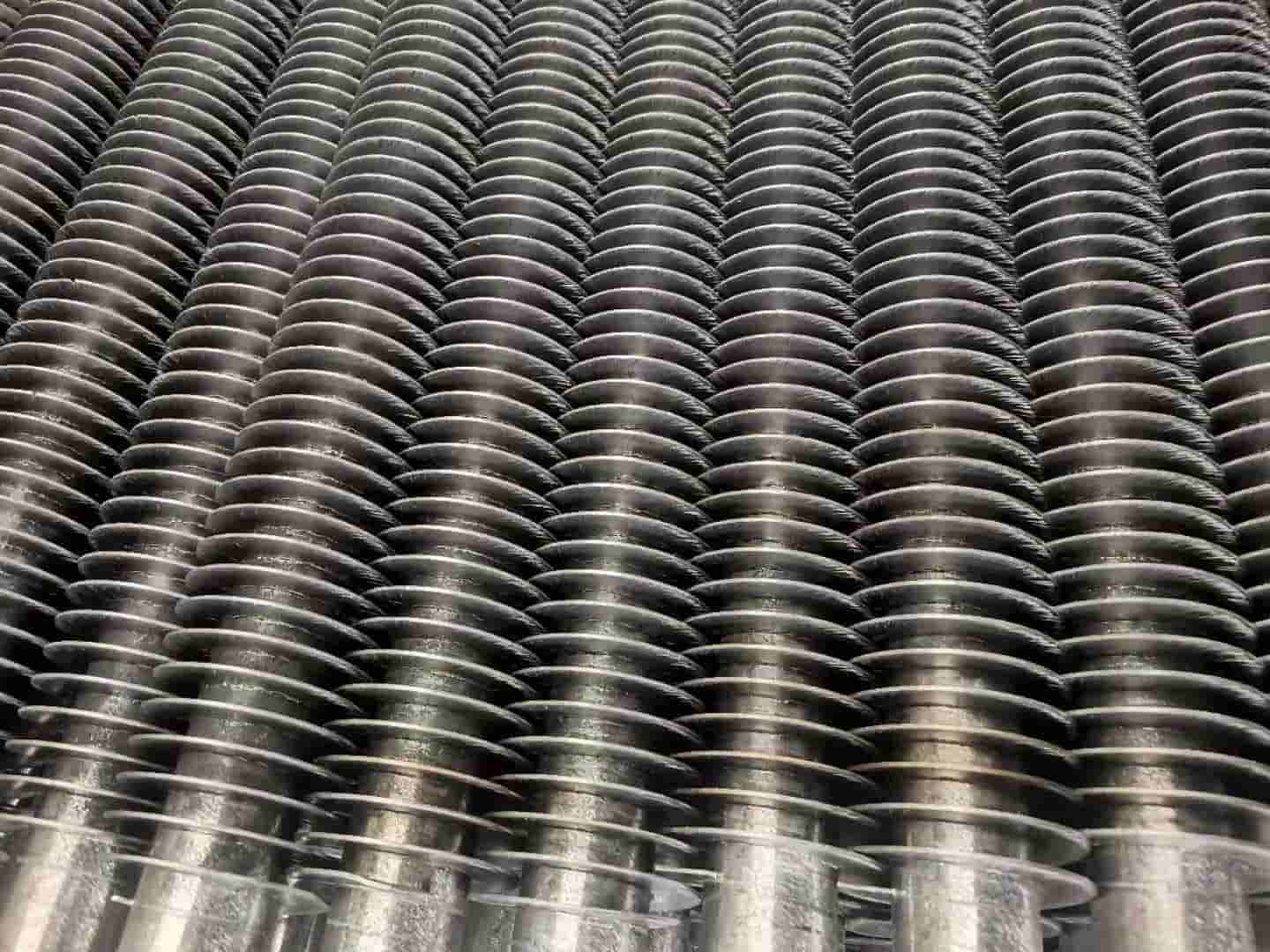

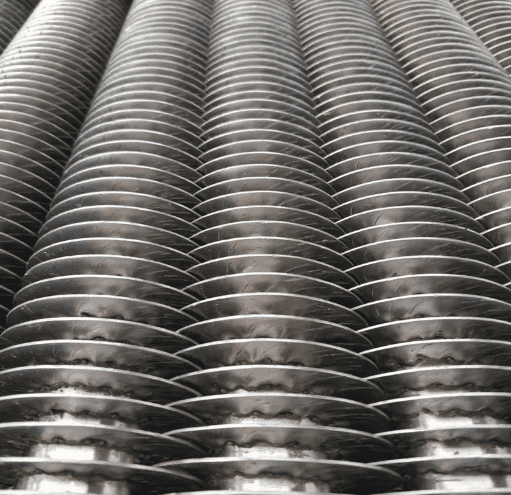

Finned tubes consist of a base tube and a series of fins attached to the outer surface of the tube.

The fins increase the heat transfer area of the tube, enhancing the efficiency of the heat exchanger.

In power stations, finned tubes are used in various equipment such as boilers, air preheaters, and economizers.

Boilers are essential equipment in power stations that produce steam, which drives the turbines to generate electricity.

Finned tubes are used in the boilers’ water walls and superheaters, which are responsible for heating the water to produce steam.

The fins on the tubes increase the heat transfer area, which allows for efficient heat transfer, reducing the time it takes to heat the water.

Air preheaters are another critical component of power station equipment that preheats the combustion air before it enters the boiler.

Finned tubes are used in air preheaters to increase the heat transfer surface area, which improves the air preheater’s efficiency.

This reduces the amount of fuel required to heat the combustion air, resulting in significant cost savings for the power station.

Economizers are heat exchangers that recover waste heat from the exhaust gas before it is released into the atmosphere.

The waste heat is used to preheat the water entering the boiler, reducing the amount of fuel required to heat the water.

Finned tubes are commonly used in economizers to increase the heat transfer surface area, improving the efficiency of the heat exchanger.

In addition to improving the efficiency of power station equipment, finned tubes also reduce the equipment’s size and weight.

The increased heat transfer area provided by the fins allows for smaller and more compact heat exchangers, reducing the equipment’s overall size and weight.

This is particularly beneficial for power stations located in areas with limited space.

In conclusion, finned tubes are critical components in power station equipment, improving the efficiency of heat exchangers and reducing the equipment’s size and weight.

By using finned tubes in boilers, air preheaters, and economizers, power stations can generate electricity more efficiently, reducing their fuel consumption and operating costs.

The use of finned tubes is an excellent investment for power stations, providing long-term benefits for their operations.