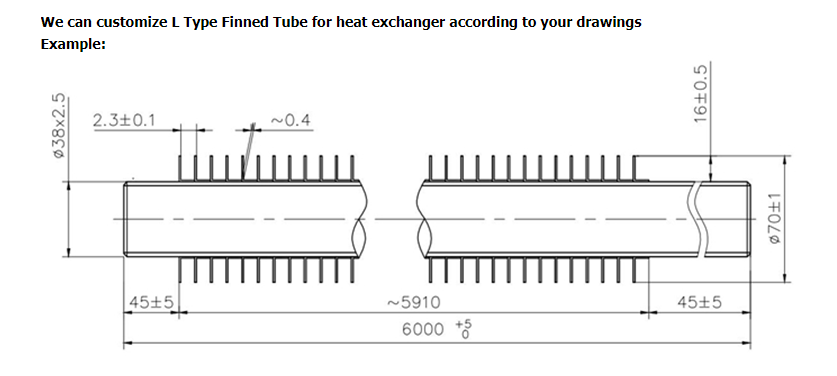

Base tube outer diameter: 16mm~51mm

Fin height: less than 16mm

Fin pitch: more than 2.3mm

Fin thickness: 0.4~0.6mm

Base tube material: carbon steel, alloy steel, stainless steel, duplex steel

Fin material: 1060, 1070, 1100, 6063, 5052

Application: air cooler, heat exchanger, heater, economizer

L-type wound fin tube: Aluminum fins or copper fins are folded into an L shape and continuously spirally wound on the outer surface of the base tube under the action of tension. Working temperature: 150℃.

Common Specifications of L Type Finned Tube for Heat Exchanger

| All dimensions are in Inches and specification upon your requests | |||

| Tube OD | Fin Height | Fin Thickness | Fins per Pitch |

| 5/8 | 3/8,1/2 | .015/.016/ .020 | 6, 7, 8, 9, 10, 11, 12 |

| 3/4 | 5/8,1/2 | .015/.016/ .020 | 6, 7, 8, 9, 10, 11, 12 |

| 1 | 5/8,1/2 | .015/.016/ .020 | 6, 7, 8, 9, 10, 11, 12 |

| 1 1/4 | 5/8,1/2 | .015/.016/ .020 | 6, 7, 8, 9, 10, 11, 12 |

| 1 1/2 | 5/8,1/2 | .015/.016/ .020 | 6, 7, 8, 9, 10, 11, 12 |

LL type wound fin tube: On the basis of L shape, the root of the fin is completely covered on the outer surface of the base tube; to some extent, this type of fin ensures better corrosion resistance. Working temperature: 170℃.

KL type wound finned tube:

Before the fins are continuously wound on the surface of the steel tube, the outer surface of the base tube needs to be knurled; after the fins are wound, the roots of the fins attached to the steel tube are also knurled to strengthen the combination of steel tube and fins. For this reason, this fin type ensures better heat transfer characteristics than L and LL fins. Working temperature: 250℃

Advantages: The manufacturing method of wound finned tubes ensures that fin processing can be carried out on a very thin-walled tube when using high-value alloys (titanium tubes, stainless steel tubes, copper tubes, etc.). The tube can withstand temperatures up to 150°C without the risk of gas corrosion or thermal stress.

Occasions of use: air coolers, heat exchangers, heaters, economizers

End use places:

Petroleum, chemical and petrochemical industries, processing, steel industry: blast furnace and converter systems, power generation: exhaust gas condensation from steam turbines, condensate contact circulation cooling condensation, fossil and nuclear power plants, air conditioning (freon, ammonia, bw), waste incineration equipment, compressor coolers, etc.

Additional Info

Payment Terms:T/T, LC

Delivery: 15-30 days after payment

Marking: Standard + Steel Grade + Size + Heat No + Lot No

Package: Iron frame packing boxes and the desiccants are put into each package for continental transportation as well. or as required