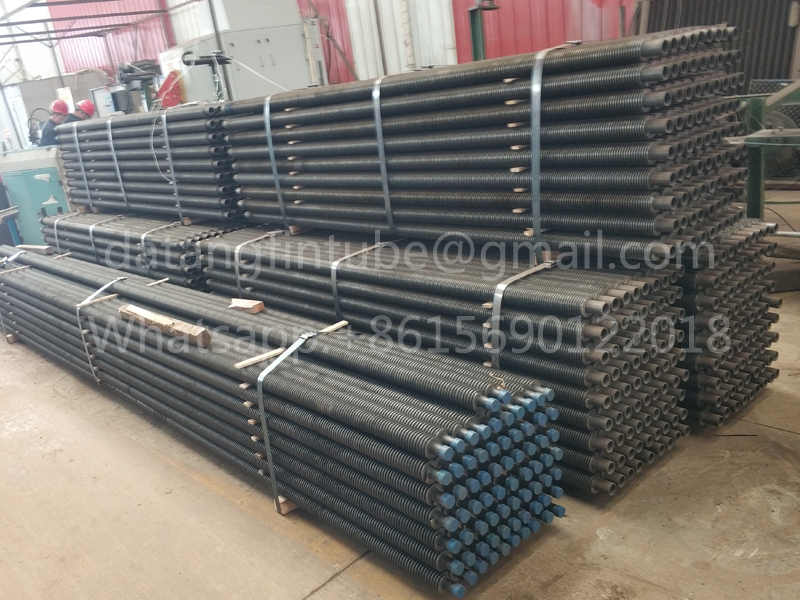

Features of finned tubes for low-temperature economizers

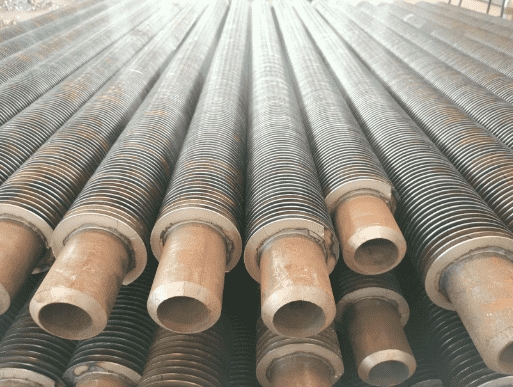

1.Finned tubes effectively increase the heat exchange area outside the tube and greatly improve the heat transfer efficiency.

Compared with bare tubes, the heat exchange area of finned tubes for low-temperature economizers has been greatly expanded.

The convection heat exchange surface of finned tubes for low-temperature economizers consists of two parts: the extended surface and the bare tube surface. When the volumes of the two are the same, the heat exchange area is several times that of the bare tube, which greatly improves the heat exchange capacity of the outer side of the tube and the heat transfer efficiency of the heat exchanger.

2.Reduce the volume of the economizer.

The use of finned tubes increases the heat exchange area per unit volume, reduces the volume of the economizer, makes the structure of the economizer more compact, and reduces metal consumption.

3.Strengthen heat transfer conditions.

The special external curved structure channel of the finned tube causes the flow boundary layer to separate and increase periodically, thinning the thickness of the boundary layer and shortening the length of the laminar boundary layer, all of which help to destroy the laminar bottom layer of the boundary layer, thereby enhancing heat transfer.

4.Reduce the flow resistance of the fluid outside the tube and save operating costs.

When the gas flow rate on the fin side is the same, the resistance of each row of finned tube bundles is greater than the resistance of each row of bare tubes, but the heat exchange area of each row of finned tube bundles is much larger than that of bare tube bundles. Under the condition of the same heat exchange capacity, the number of tube bundles can be reduced, so that the total resistance of the heating surface is reduced.

Due to the significant improvement in the heat transfer capacity of spiral finned tubes, the fluid velocity on the fin side can be appropriately reduced under the condition of ensuring the heat exchange capacity, and the flow resistance is usually proportional to the square of the velocity. Therefore, reducing the fluid velocity can reduce the resistance of the heating surface and save operating costs.

5.Reduce the wear of the heating surface In a boiler burning solid fuel, when the ash-containing airflow flows through the heating surface, it will impact and cut the heat exchange surface, causing wear of the heating surface, and the amount of wear is proportional to the cube of the fluid velocity.

6.The improvement of the heat transfer capacity of the finned tube bundle can reduce the velocity of the fluid outside the tube, thereby greatly reducing the wear of the heating surface.

Contact Us:datangfintube@gmail.com