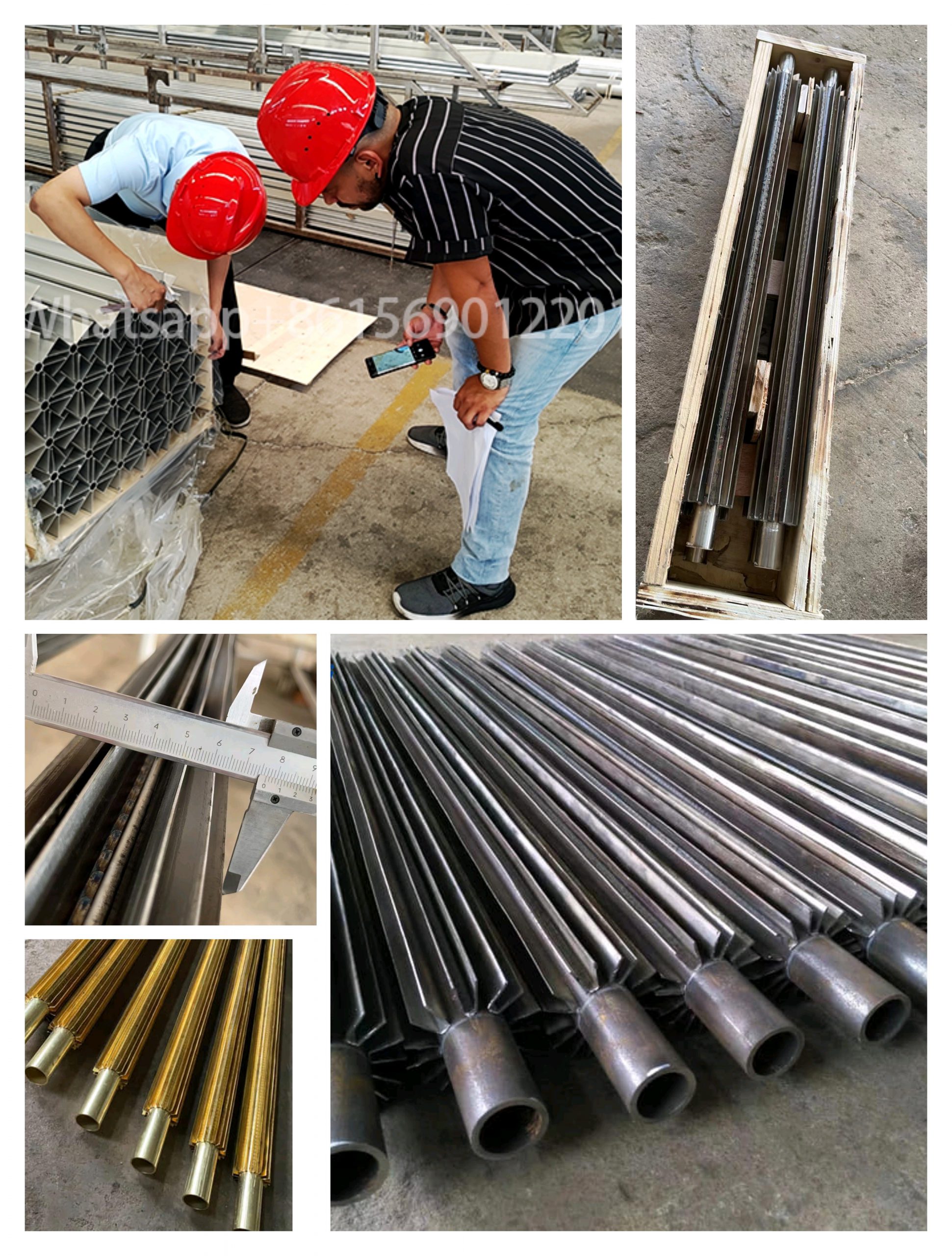

Welded U longitudinal finned tubes for heat exchangers

Requirements for tube heat exchange (smooth):

1 Seamless tubes;

2 The tubes shall be factory treated. Information on heat treatment shall be indicated on the quality certificate of the pipe;

3 The pipes shall be 100% FTC tested according to EN 10216-2. Information on TCE test shall be indicated on the quality certificate. Information on TCE test shall be shown on the quality certificate.

4. The manufacturer guarantees 100% of the pipes in the delivery condition (after delivery).

All pipes in the delivery condition (after refining) must pass the test pressure (maximum 20 MPa) to cause a stress equivalent to 40% of the tensile strength.

Each package shall contain no less than 3 tubes for a total of 6% of the Pars water pressure test;

5. The deviation of geometric dimensions shall comply with the requirements of 12, 13, and 14;

6. The outer and inner surfaces of the pipes shall be free of cracks, tears, curling and burrs. These defects shall be completely removed.

These defects must be completely removed by local cold grinding for deburring or full grinding, boring and chamfering. These defects must be completely removed by local cold peeling or surface grinding, boring. The wall thickness at the point of removal of defects must not exceed the minimum permissible value.

7. The ends of the tube must be cut at right angles;

8. The pipe should pass the distribution test in accordance with EN 10216-2 without cracks;

9. Provide the quality and inspection certificate of all heat exchanger pipes provided by the manufacturer.

Requirements for fins:

1. The geometric dimensions of the longitudinal fins should comply with the drawings;

Requirements for welding U longitudinal finned tubes:

1. The manufacturer must ensure that the fins are 100% welded on the heat exchange tubes.

2. The manufacturer must conduct random inspections of the finned tubes (not less than 1 in 30).

3. The manufacturer should check the quality of the welding rod (at least once every 10 minutes).

4. The manufacturer should conduct continuous visual inspections during the finning process.

5. The test results of the fin welding process will be shown in the certificate.

6. The welding requirements must comply with the welding specifications of EN ISO 15609-5, EN ISO 15614-12, EN ISO 13920.

Packaging/storage of longitudinal finned tubes

1. All tubes must be packed in wooden boxes for transportation.

2. Storage requirements: The packaging must ensure that the pipes are not damaged during transportation (3-week transportation cycle).

Notes on high-frequency welded longitudinal finned tubes

The manufacturer should provide:

The documents that meet the standard requirements of longitudinal finned tubes should include:

1. Quality certificate.

2. Provide the specifications of the tube and the grade of the material.

3. The specifications of the fin part and the grade of the fin material.

4. Description of the tube and fin dimensions.

5. The actual net weight and gross weight of each tube package.

6. Material brand.brown fin tube

7. Welding information of tubes and fins.

8. Numerical values of the mechanical properties (tensile strength, tensile strength, yield strength) of the pipe (ultimate tensile strength, yield strength, elongation, Brinell hardness).

9. Complete classification of the chemical composition of the pipe.

10. Results of non-destructive tests.

Welded U longitudinal finned tubes for heat exchangers, ensure that the fins are 100% welded on the heat exchange tubes, welcome to contact Datang brown fintube company.

Contacts: Sunny Yang

Whatsapp Number: +86 15690122018

Email: datangfintube@gmail.com