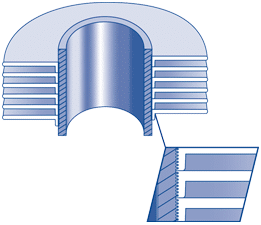

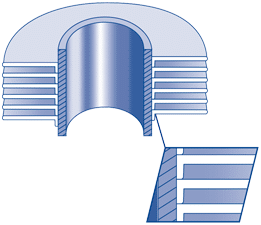

Rectangular finned tube

Size of the Elliptical Finned Tube:

Tube Length: Within 25 Meters

Tube cross-section dimension: 36mm*14mm

Tube wall thickness: 2mm

Fin tube cross-section dimension:55mm*26mm

Fin Base Thickness: 0.3mm

Fin Pitch: 416 fins per meter

Finned Tube material: carbon steel, stainless steel, alloy steel and other materials

Elliptical Fin Tube|Elliptical Tube With Rectangular Fins| Hot dipped galvanized oval fin tubes

This fin tube design utilizes an elliptical shaped tube with an efficient air foil shape to minimize airside flow resistance. These fins have improved performance characteristics compared to round tube types.

The corrosion resistance of these fins will be very high after being hot dip galvanized. These fin tubes are very compact compared to other types of fin tubes and their heat transfer efficiency is significant.

| L finned tubes, LL (Double L) finned tubes, KL finned tubes (knurled fin tubes) (with aluminum fins) Fins: Aluminum ASTM B209 Al 1060; ASTM B209 Al 1100, 1050A. | |

| Fields of application . the petroleum, chemical and petrochemical process industries . natural gas treatment . the steel industry: blast furnace and converter systems . power generation . air conditioning (Freon, ammonia, propane) . incineration of household refuse . compressor coolers, etc. | |

| Supply Range of base tubes (pipes) (core tube): Carbon Steel SA179, SA192, SA210A1, SA210C, SA106 Gr.B Low Alloy Steel SA213, SA335, T1, T5, T9, T11, T12, T22, P5, P9, P11, P12, P22 Stainless Steel SA213, SA312, TP304L, TP316, TP316L, TP321, TP347, TP316Ti, ASTM A789/A790 UNS S31803, ASTM B677 Alloy 904L Nickel ASTM B161 Ni200, ASTM B161 Ni201 |

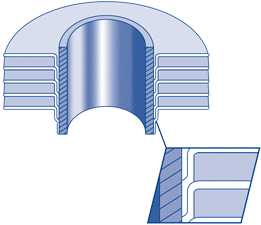

H/double H fin tubes

Steel H

Pairs of parallel shaped steel fins are resistance welded to the single pressure tubes (pipes) surface under very carefully controlled conditions.The purpose build welding machine ensures very precise indexing along the entire length of the tubes (pipes) and exact parallel attachment.

Double H h, double H / double H fin tubes

A development of the single tubes (pipes) version, the ‘Double H’ design has the steel fins welded onto two tubes at the same time. For applications with cleaner gases the use of ‘Double H’ can reduce the number of supports required due to its inherent stiffness.

Configurations

As a general guide, spacing of tubes (pipes) centres is usually in the range of 2-3 times the tubes (pipes) O/Dia.

. tubes (pipes) O/Dia. [OD] mm – 31.8 to 57.2

. tubes (pipes) Length [L] Metres – Up to and including 18 Metres maximum

. Vertical Centres [V] mm – 65 to 133

. Horizontal Centres [H] mm – 65 to 178

. Fin Thickness [t] mm – 2.0, 2.5, 3.0 (certain fin shapes can be 1.5mm thick material)

. Fin Density [P] mm – Minimum 10mm, i.e. 100 Fins Per Metre (FPM)

. Fin Shape – Over 75 fin shapes as standard, with new fin shapes continually being developed.

Bespoke fin shapes are produced to suit the design application where feasible.

Base tubes (pipes) Material

Typically Carbon, Corten, Low alloy steels.

Tubes quality / type can be Cold Drawn Seamless [CDS], Hot Finished Seamless [HFS], Electric Resistance Welded [ERW].

Fin Material

Carbon Steel Hot Rolled [HR4], Corrosion resisting steels i.e. Corten, 09CrCuSb.

Advantages:

The reflux zone and windward area is much smaller, reduce the hydromechanics on the air side, then reduce the energy consumption

Inside the heat exchanger equipment, oval tube bundle is more compact than circular tube bundle, so the heat exchanger has smaller volume and is with lower cost

The fins are not sensitive to typical mechanical loads, for example hailstorm or walk on the bundles.

The rectangular fins are with high strength, protecting the base tube from fracture in winter, prolonging the tube life-span.