| Tube O.D.: | 16 to 273 (mm) | 3/8” to 10”(NPS) |

| Tube Wall Thk.: | 2 to 28.6 (mm) | 0.08” to 1.1” |

| Tube Length: | ≤28,000 (mm) | ≤92 ft |

| Fin Thk.: | 0.5 to 3.5 (mm) | 0.02” to 0.14” |

| Fin Height: | 8 to 35 (mm) | 0.31” to 1.3” |

| Fin Pitch: | 3 to 333 FPM | 1 to 8 FPI |

| Fin Type: | Solid, “U”or“V” Serrated | |

| Fin Material: | C.S. (most common grade: 08F, SPCC)

S.S. (most common grade are AISI 304, 316, 409, 410, 321,347 ) A.S. |

|

| Tube Material: | C.S. (most common grade: A106 Gr.B, A210, A192)

S.S. (most common grade are TP304, 316, 321, 347 ) A.S.(most common grade are T/P5,9,11,22,91 ) Duplex Steel(most common grade are 2205 etc. ) |

|

Corrosion protection:

If required, the external surfaces of finned tubes can be treated with a protective coating. Our engineers are always ready to assist you with design considerations to meet your specific product needs.

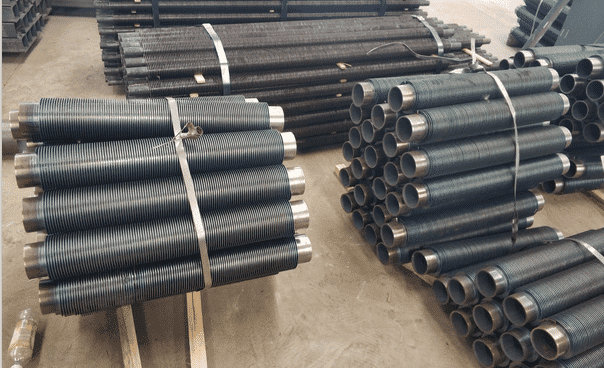

High frequency welded fin tube extendheat transfer surface that provides maximum efficiency in theat exchange applications from exhaust hot gas to a contained liquid process

This welded steel finned tube configuration can be used for any practically heat exchanger application, and is particularly suited to high temperature and high pressure applications. The important features of this configuration are efficient, effective bond of fin to tube under all conditions of temperature and pressure, and ability to withstand high fin-side temperatures.

Both solid and serrated fin tube is used for Heat recovery steam generator, Petrochemical, Boiler Plants, Economnizer, Gas cooler and Heat exchangers in a wide range of applications.

Solid fin tube is recommened for contaminated gas streams where oil, coal, wood or other high fouling fuels are used. Serrated fin tube is primarily used in clean streams.