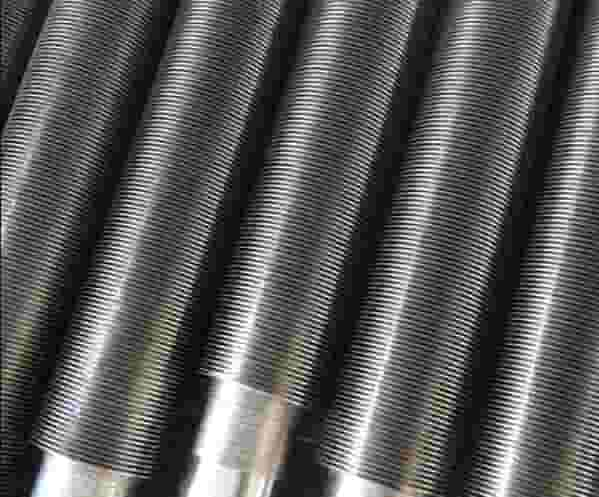

Specializing in the production of finned tube products.

As a heat exchange element, finned tubes work under high-temperature flue gas conditions for a long time.

For example, finned tubes used in boiler heat exchangers are used in harsh environments, high temperature and high pressure, and in a corrosive atmosphere.

This requires finned tubes to have high performance. index.

1), anti-corrosion performance (Anti-corrosion)

2), wear resistance (Anti-wear)

3), low contact resistance (lower contact resistance)

4), high stability (Higher Stability) 5), anti-dusting ability

There are many types of finned tubes, and new ones are constantly emerging.

Classified by processing technology

1), rolled finned tube (extruded fin tube);

2), welded finned tube (high frequency welded finned tube, submerged arc welded finned tube);

3), rolled formed finned tube;

4 ), suit forming finned tube;

5), casting finned tube;

6), tension wound finned tube;

7), insert tube.

Classified by fin shape

1), square finned tube (Square finned tube);

2), circular finned tube;

3), spiral finned tube (spiral finned tube);

4), longitudinal finned tube (Longitudinal Finned Tube)

5), corrugated

6), spiral serrated finned tubes (Helical Serrated Finned Tubes);

7), needle-shaped finned tubes;

8), integral plate-shaped finned tubes (plate fins);

9), inner fins Tube (inner finned tube). and many more.

Single metal finned tubes are classified by material

1), copper finned tube;

2), aluminum finned tube;

3), carbon steel finned tube;

4), stainless steel finned tube;

5), cast iron (cast steel) finned tube; etc.

Classification by purpose

1), finned tubes for air conditioning;

2), finned tubes for air cooling;

3), boilers: finned tubes for water walls, economizers, and air preheaters;

4), finned tubes for industrial waste heat recovery ;

5), other special-purpose finned tubes, etc.