Advantages and structural forms of Finned Tube Air Cooler

Air coolers are large heat exchange devices that cool process fluids with ambient air. It has been widely used in refineries, power plants and other industrial fields.

In order to enhance the cooling effect of air, most air coolers use finned tubes as heat transfer elements. In order to save water, it has become a common choice to replace water cooling with air cooling.

Compared with traditional water cooling, the main advantages of air cooling are:

① Water is increasingly becoming a scarce resource. my country is a water-scarce country. In some energy-rich provinces and the vast Northwest region, water resources are even more scarce, but air is everywhere and can be used for free. In order to solve the bottleneck of water shortage Air cooling is the only possible option.

② The use of air cooling will hardly cause pollution to the environment. If water cooling is used, when the heat exchanger corrodes and leaks, it will cause pollution to water resources.

③ Water needs to be processed and treated, and the flow resistance of water in the heat exchanger is relatively high, which makes the cost of water cooling relatively high; while the air does not need to be treated and recycled, so the operating cost is low.

In addition, using air as a cooling medium, compared with water, also has some disadvantages and characteristics:

① Air temperature is greatly affected by atmospheric temperature and climate, and is often in a state of change, unlike water temperature, which is easy to control.

② The inlet temperature of the air is the dry bulb temperature of the atmosphere, and the outlet temperature of the cooled medium cannot be lower than the dry bulb temperature of the atmosphere, and its cooling effect is affected and restricted by the atmosphere temperature.

③ The required air flow is very large: when the air is at 20°C, the specific heat capacity is 1. 0 kJ/(kg • °C). The density is 1.2 kg/m3, while the specific heat capacity of water is 4. 183 kJ/(kg • Y) , the density is 998 kg/m3o, under the condition of absorbing the same amount of heat and the same temperature rise, the quality of air is 4.18 times that of water, and the volume of air is 830 times that of water.

Therefore, the air cooler needs a large air volume and a large Frontal area.

④ The convective heat transfer coefficient of air is much lower than that of water, even in the case of finned tubes,

The heat transfer coefficient of the air cooler is also low, which is 100% of that of the water cooler.

The structure of the air cooler:

(1) Finned tube. In order to improve the heat transfer effect of the air cooler, most air coolers use finned tubes as the heat transfer elements of the air cooler.

See the introduction to finned tubes that exchange heat with air in Section 1.2. As the air flows through the fins, there is almost no pollution and corrosion, and under most operating conditions, the surface ash and fouling are not serious, so the finned tubes used in the air cooler have a high fin density, and the finning ratio can reach 20 above.

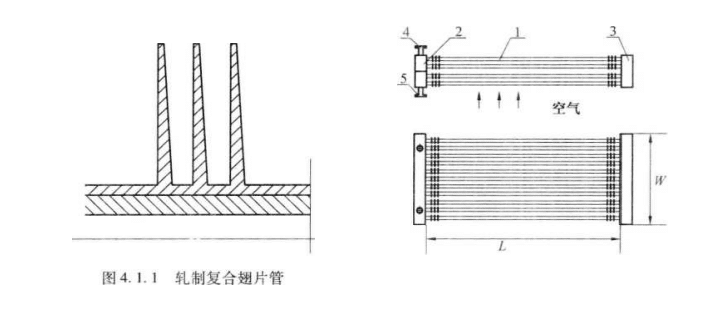

The fins are mostly made of aluminum, while the base tube is mostly made of carbon steel or stainless steel. Among them, steel pipe/aluminum rolled composite finned tube is the most common application, and its structure is shown in Figure 4.1.1.

The contact thermal resistance of this finned tube is very small. In addition, the integral aluminum fin completely isolates the base tube from the air.

It has the advantages of easy workmanship and low manufacturing cost, so it has become the first choice for the current air cooler manufacturing industry.

Commonly used finned tube specifications are:

tube outer diameter:. . =20 ~25 mm;

fin height: 1. – 15 mm;

fin spacing: 3 ~4 mm;

fin thickness: 0. 3 -0. 6 mm;

finning ratio: 15 ~25.

For example: the specification of a commonly used finned tube is: the outer diameter of the base tube: =25 mm;

fin height t=12.5 mm;

fin spacing is 3.0 mm;

fin thickness is 0.5 mm;

finning ratio is 23.

(2) Finned tube bundles.

A heat transfer unit consisting of multiple finned tubes and tube boxes is called a finned tube bundle.

As shown in Figure 4.1.2, the finned tube bundle is mainly composed of finned tubes and tube boxes connecting the finned tubes.

The inlet and outlet of the medium in the tubes can be placed on the same tube box, and the other tube box is used as a rotary tube box , relying on the partition inside the tube box to realize the division of the tube pass.

In the direction of air flow, 2~6 rows of finned tubes are generally arranged. The figure shows 2 tube passes, and every 2 rows of finned tubes is a tube pass.

Each row of finned tubes is staggered. The overall size of the tube bundle is 1 (length) x “(width), in order to facilitate transportation and processing, the length is generally not more than 12 m, and the width is preferably not more than 3 m.

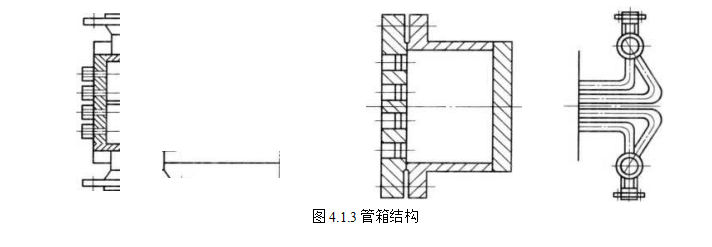

There are many forms of the structure of the pipe box, as shown in Figure 4.1.3. In order to facilitate the installation of the finned tube and the cleaning inside the tube, a plug-type tube box structure is often used.

On the outer box plate of the tube box, a detachable plug is installed for each tube opening. For high-pressure medium, a round tube type box can be used.

(3) Arrangement of finned tube bundles and fans.

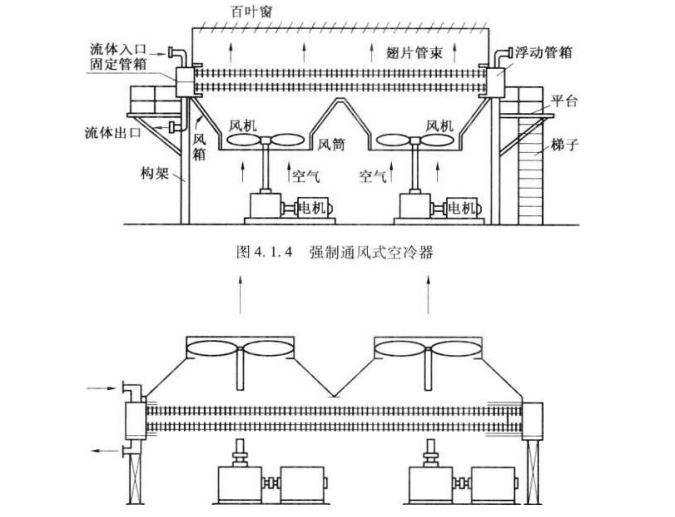

An air cooler is composed of several finned tube bundles together to form a complete heat transfer structure of the heat exchanger.

There are two arrangements of finned tube bundles and fans of the air cooler: in Figure 4.1.4, the tube bundles are arranged horizontally, and the fan is installed at the lower part to blow air upwards, which is called blast type or forced ventilation air cooler; in Figure 4.1.5 , the tube bundle is placed horizontally, the fan is installed on the upper part, and the air is drawn upward, which is called an induced draft or induced draft air cooler.

The two types of air coolers have their own advantages and disadvantages: for forced ventilation air coolers, the air entering the fan is cold air without heating, the air density is relatively high, and the power consumption of the fan is small.

The disadvantage is that the hot air blown out is easily sucked back , to generate hot air recirculation, it is necessary to carefully consider the structure of the air outlet and inlet; for the induced draft air cooler, the wind entering the fan is heated hot air, the temperature is high, so the fan consumes more energy, but Due to the high dynamic pressure of the air outlet, hot air recirculation is not easy to occur. In addition, because the fan is installed at a high place, it will add certain difficulties to the structural design and installation process.

There are three important parameters related to each other in the selection of the fan model, namely air volume (m3/h), pressure head (Pa) and power (kW), these parameters should be determined by the design.

In terms of structure, multiple fans are often used, which should be reasonably combined with the windward side of the tube bundle.

In order to prevent sunlight, rain, snow, low temperature and other natural factors from affecting the tube bundle and heat transfer, for forced ventilation air coolers, adjustable shutters must be installed on the upper part of the finned tube bundle.

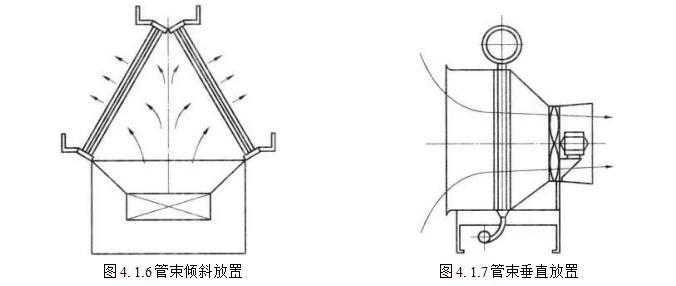

In addition to the horizontal placement of the tube bundle shown in Figure 4.1.4, 4.1.5, the finned tube bundle can also be placed obliquely, or -146 .

The air cooler with tube bundle placed horizontally is especially suitable for multi-tubes, while the air cooler with inclined or vertical placement is especially suitable for condensation of steam in a single tube or tube.

The steam enters from the upper tube box, and the condensate enters from the lower tube box. discharge. In addition, compared with horizontal placement, the occupied area of the air cooler placed obliquely or vertically will be reduced, but it will have a certain impact on the uniformity of the air flow around the finned tube bundle.

This chapter focuses on the design calculation method of the air cooler, and does not discuss the structural design and details of the air cooler in detail.

In the design of the air cooler, the outside of the tube is the heat exchange of the air flowing around the finned tube bundle. There are mature calculation methods for the heat transfer coefficient, which can be calculated according to the relevant formulas in Chapter 2.

However, the cooled medium in the tube will have various heat transfer conditions and follow different heat transfer laws, so it is necessary to classify the design of the air cooler according to the heat transfer characteristics in the tube.

According to the heat transfer characteristics in the tube, it can be divided into:

(1) The medium in the pipe is a single-component or multi-component cooling;

(2) The medium in the pipe is condensation of single component or multi-component;

(3) The medium in the tube is condensation and cooling of single or multi-component.

The phase change heat in the tube involves the gas/liquid two-phase flow in the tube.

Due to the complexity of the heat transfer process and the imperfect calculation method, it brings great difficulties to the design and calculation of the air cooler.