Design of Finned Tube Economizer. Economizer overview and classification.

In Chapter 1, the application conditions of finned tubes are classified according to the gas with which they exchange heat:

finned tube heat exchangers that exchange heat with air, and their typical representative air coolers have been discussed in Chapter 4.

And the finned tube heat exchanger that exchanges heat with the flue gas, the typical representative of which is the boiler economizer.

Economizer is Economizer in English, which means economizer.

In boilers burning different fuels, they are collectively referred to as economizers.

The economizer is a heat exchange device that uses the heat of the flue gas at the tail of the boiler to heat the feed water, and belongs to the heat exchange between the flue gas and water.

Since the heat transfer coefficient of the flue gas side outside the tube is very different from that of the water side inside the tube, fins need to be added on the flue gas side, that is, finned tubes are used to enhance the heat transfer on the flue gas side.

Early economizers often used cast iron finned tubes, which have been replaced by various new finned tubes with better heat transfer performance and easier processing and manufacturing.

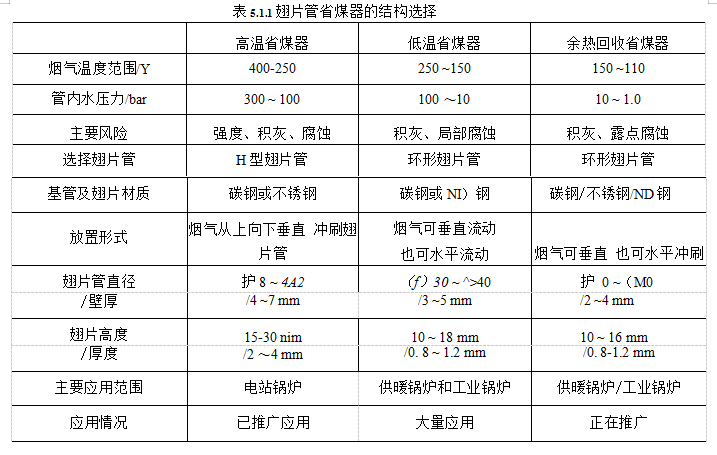

According to the different design requirements, the economizer can be installed in different parts of the boiler flue gas flow channel. According to the flue gas temperature, the economizer can be divided into:

High temperature economizer: exhaust gas temperature is about 400 – 250

Low temperature economizer: exhaust gas temperature is about 250 ~ 150 r;

Waste heat recovery economizer: exhaust gas temperature is about 150-110

For high-temperature economizers, besides the strength problems caused by high temperature and high pressure, finned tubes face technical problems such as dust accumulation and wear; for waste heat recovery economizers, in addition to facing dust accumulation, the more important It is sulfuric acid dew point corrosion of flue gas.

For different application conditions and technical requirements, the technical measures that should be taken are: one is to select the appropriate finned tube structure, and the other is to select reasonable design parameters and design schemes.

Table 5.1.1 lists the finned tube selection and the general structure of the finned tube economizer. Figure 5.1.1 and Figure 5.1.2 show two sets of finned tubes commonly used in finned tube economizers.