The processing technology of the steel-aluminum composite finned tube is to process the aluminum tube and the copper tube into a bimetallic composite tube, and then through mechanical cold rolling, and use the physical characteristics of the aluminum tube to make a tube with a steel tube as the core and a cold-rolled aluminum tube.

The fins are tightly combined into one finned tube. Steel-aluminum composite finned tube radiators are widely used in heating and air-conditioning projects for wet cooling to easily remove condensed water on the outer surface of the fins, and are not easy to accumulate dust and scale in dry heating and other heat exchange occasions.

2. Features of steel-aluminum composite finned tubes:

1. It has tight combination, small thermal resistance and good heat transfer performance;

2. High strength and low flow loss;

3. Strong anti-corrosion performance, not easy to deform under long-term cold and hot conditions, and long working life.

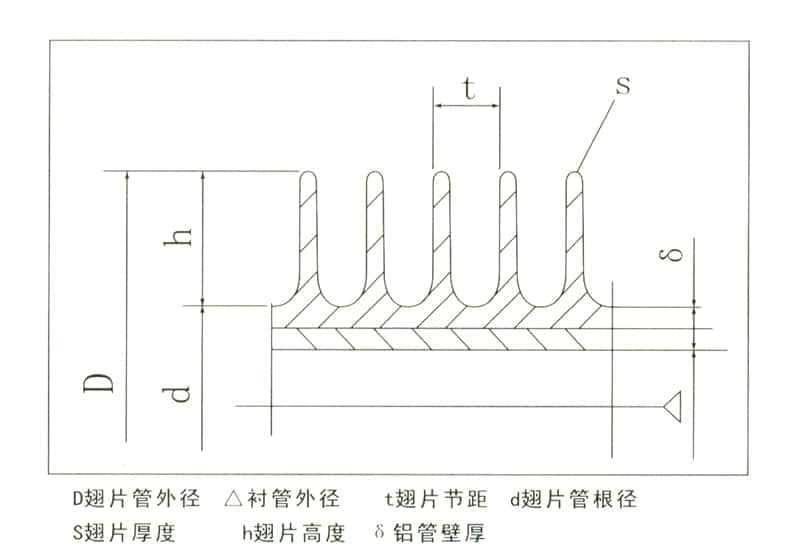

Three: Schematic diagram of steel-aluminum composite finned tube structure:

4. Specification and performance table of steel-aluminum composite finned tube: