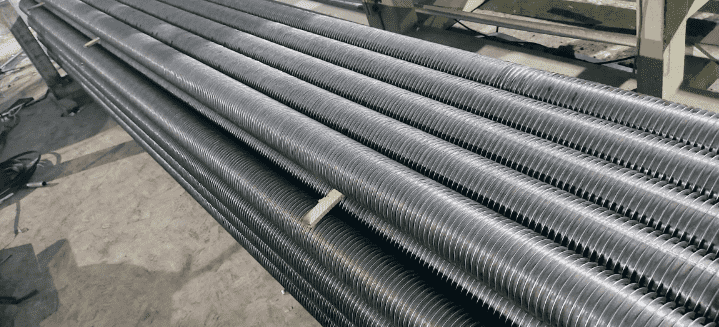

Wrapped finned tube refers to the finned tube that is cold-formed at room temperature.

It relies on mechanical force to directly wind high-quality steel strips or aluminum strips on the steel pipe to form spiral fins.

Its processing technology is simple, and it is convenient to obtain materials. Due to the limitation of processing technology, the fin spacing is generally large, ranging from 3.2-8mm, so the unit heat transfer area is smaller than other types of finned tubes; the thickness is generally between 0.2-0.5mm, too thick High-quality strip steel is not conducive to the extension of the metal, and it is easy to break during the winding process.

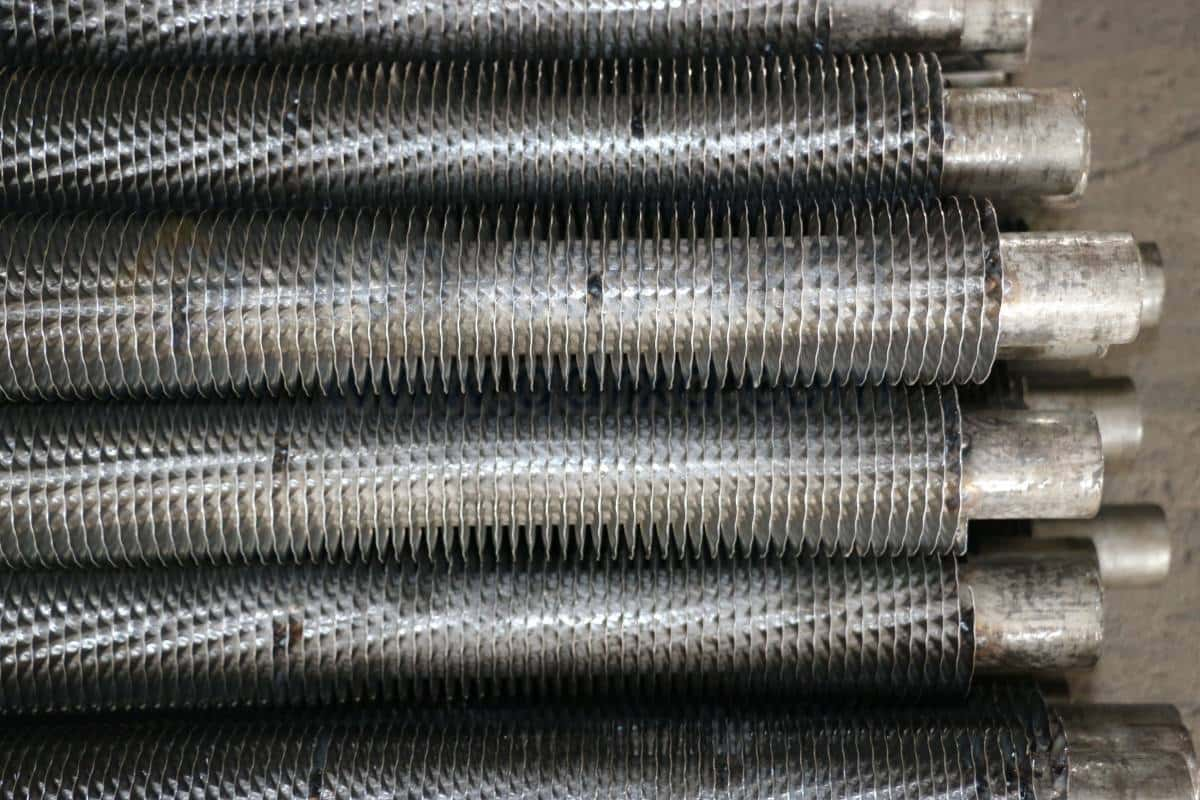

The appearance of the wound-finned finned tube has obvious wrinkles on the fins near the base tube. The shape of the wrinkles allows the steel strip to stand on the base tube confidentially by mechanical tension and will not fall down.

In addition, the wrinkled steel strip is also It can make the penetrating gas outside the tube generate impingement turbulence to promote the heat transfer effect.

When the fin material of the finned tube is aluminum, the fins are L-shaped or LL-shaped, which can be processed into a smaller pitch, the minimum pitch is 2.3mm, the unit heat transfer area is larger, and the price is lower. The height of the steel sheet.

The disadvantage is that the rigidity of aluminum is not enough, it is not suitable for working environments with large thermal expansion and cold contraction, and as the application period increases, the impact of its contact thermal resistance will become more obvious.

Therefore, it is usually used in systems with relatively stable working environments. Such as hot water heating or cooling, it should be used with caution when the heat medium is steam and heat transfer oil.

When the fin material of the wound finned tube is carbon steel or stainless steel, the shape of the fin is a common spiral shape, the distance between the fins is generally 5-8mm, and the thickness is generally 0.25-0.4mm.

The fins in this state are easier to process , small thermal contact resistance and low production cost. If the strip thickness increases to more than 0.5, it is necessary to use high-frequency welding process.

Wound finned tubes are widely used at present. According to the material, they can be processed into wound stainless steel sheets, aluminum sheets, carbon steel sheets, etc.

All finned tubes that are spirally wound can be called wound finned tubes. , which is determined by the processing technology.