Finned tube heat exchange principle:

There is a heat exchanger that uses hot water to heat the air, the hot water flows inside the tubes, and the air flows outside the tubes.

For example, the hot air curtain used for heating or the radiator on the car all belong to this type of heat transfer, that is, the heat of hot water is transferred to the cold fluid outside the pipe—air through the pipe wall.

It can be seen that the heat transfer process is closely related to the two convective heat transfer processes on both sides of the partition wall.

For the above example: the convective heat transfer coefficient of the water side inside the tube is about 5000, while the convective heat transfer coefficient of the air side outside the tube is about 50, the difference between the two is 100 times.

Since the heat transfer “capacity” of the air side is far lower than that of the water side, the heat transfer “capability” of the water side is limited, making the air side the “bottleneck” of the heat transfer process, which limits the increase in heat transfer.

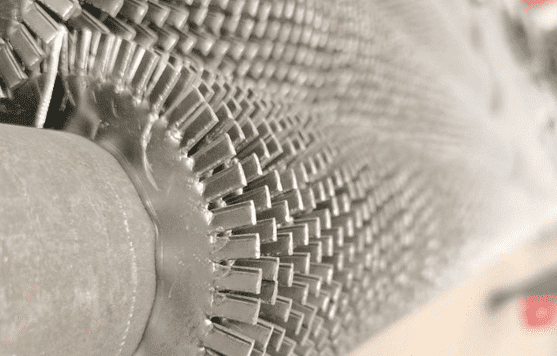

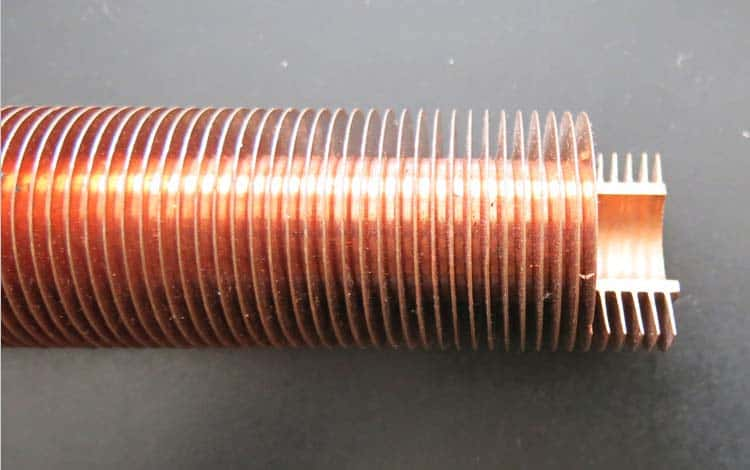

In order to overcome the “bottleneck” effect on the air side, it would be a wise choice to install fins on the outer surface of the air side.

After the fins are added, the original heat transfer area of the air side has been greatly expanded, and the shortcoming of the low heat transfer coefficient of the air side has been made up, so that the heat transfer rate has been greatly improved.

When should finned tubes be used for heat exchange?

After understanding the principle and function of finned tubes, there are several principles for choosing finned tubes in which occasions:

(1) If the heat transfer coefficient on both sides of the tube is very different, fins should be installed on the side with the smaller heat transfer coefficient.

Example 1: Boiler economizer, water flows inside the tube, flue gas flows out of the tube, and fins should be used on the flue gas side.

Example 2: For an air cooler, the liquid flows inside the tube and the air flows out of the tube, and the fins should be added on the air side.

Example 3: In a steam generator, water boils inside the tube, and flue gas flows outside the tube, and the fins should be added on the side of the flue gas.

It should be noted that in the design, the side with the small heat transfer coefficient should be placed outside the tube as much as possible to facilitate the installation of fins.

(2) If the heat transfer coefficient on both sides of the tube is very small, in order to enhance heat transfer, fins should be installed on both sides at the same time.

If there are structural difficulties, no fins can be added on both sides. In this case, if fins are only added on one side, the increase in heat transfer will not have a significant effect.

Example 1: In a traditional tubular air preheater, air flows inside the tube and flue gas flows outside the tube.

Because it is gas-to-gas heat transfer, the heat transfer coefficient on both sides is very low, and it is very difficult to add fins in the tube, so the tube has to be used up.

Example 2: Heat pipe air preheater, although the flue gas is still used to heat the air, but because the flue gas and air flow outside the tube, finned tubes can be conveniently used on both the flue gas side and the air side to make the heat transfer greatly increase.

(3) If the heat transfer coefficients on both sides of the tube are large, it is not necessary to use finned tubes.

Example 1: In a water/water heat exchanger, when hot water is used to heat cold water, the heat transfer coefficients on both sides are high enough that there is no need to use finned tubes. However, in order to further enhance heat transfer, threaded pipes or corrugated pipes can be used instead of light pipes.

Example 2: In the condenser of a power plant, water vapor condenses outside the tube and water flows inside the tube. The heat transfer coefficients on both sides are high, and generally, finned tubes are not required.