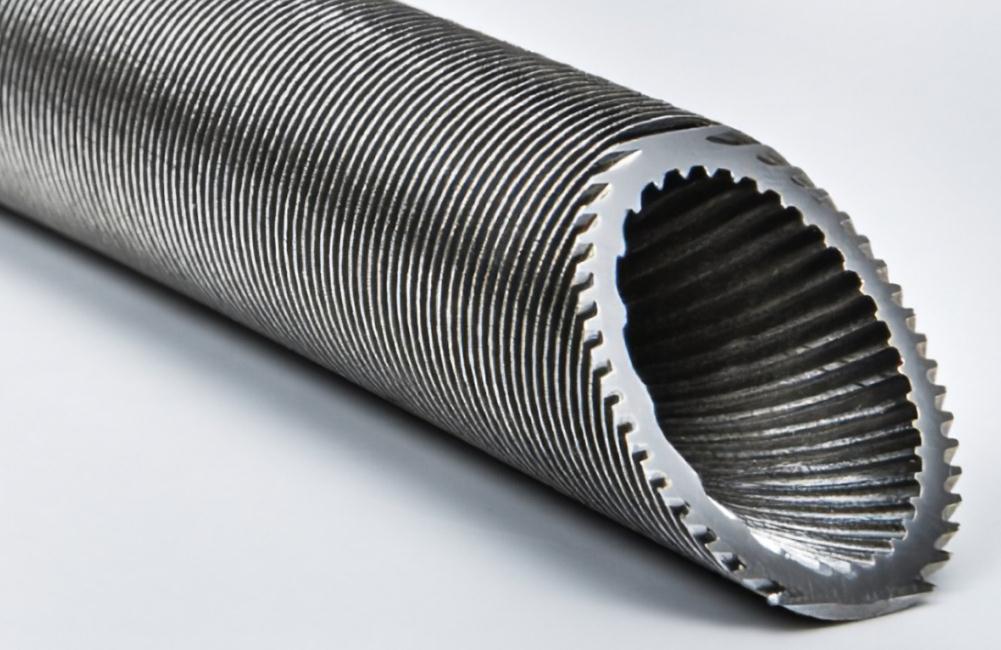

What are the methods of connecting finned tubes in series? The stringing of fins is to string the fins to the tube one by one, and the fins are one by one.

In addition to the structural differences of the tubes, there may be gaps between the finned tube and the tube wall.

If there is a gap, it will affect the performance of the product. So, what are the methods of connecting finned tubes in series?

Integral finned tube series connection method

1. Electric welding.

Apply a layer of flux on the cleaned tube wall, then connect the fins to the tube, then connect the power supply at both ends of the finned tube, the high temperature promotes the melting of the metal in the flux, and welds the tube and the fins together.

2. Immersion plating method.

Oxide and grease on the surface of tubes and fins before immersion plating need not be left at all. It can be cleaned with hydrochloric acid, sulfuric acid and oxidizing agent (such as nitric acid).

Note that copper fins are only cleaned with dilute sulfuric acid. After the overall finned tube is cleaned, dip it again in an ammonium chloride solution containing stannous chloride before placing it in a molten zinc (or tin) tank (the melting point of zinc is 400°C, and that of tin is 230°C).

The molten zinc (or tin) solution flows into the gap between the fin and the tube, not only filling the gap, but also forming a layer of coating after the surface is cooled. This method is expensive and expensive, and the heat exchange per square meter The area consumes about 1.25-1.30kg of zinc.

3. Contact welding.

Weld one side of the string (or winding) to one side of the tube. During the welding process, the pipe should not be deformed, and the mandrel should generally be inserted.

There should be hems at the perforations of the fins. The disadvantage is that more complicated special equipment is required, and special welding equipment is used.

4. Expansion tube method.

Use the hydraulic method (generally pressurized to above 30 MPa) to expand the tube channels of the finned tubes that have been strung together, so that the overall finned tubes are tightly hooped on the tubes.

Not suitable for steel pipes, suitable for non-ferrous metal finned tubes with good ductility.