The installation process of stainless steel finned tubes is simple, and its economy reduces the connection points during operation.

The installation of such equipment will become more economical and quicker, and to a certain extent, it will also reduce the probability of water leakage at the connection point. The maintenance of the product is simple, and basically no maintenance is required after installation.

Stainless steel finned tubes are mainly used in air coolers and air heaters in petrochemical, electric power, papermaking, tobacco, building heating and other industries, and air heaters in vegetable protein powder and starch spray drying systems in the food industry.

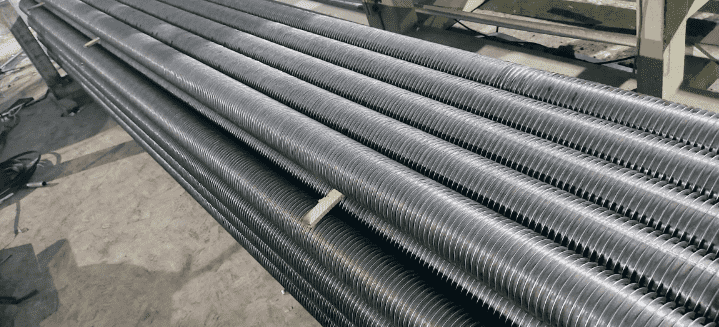

Stainless steel finned tubes have the characteristics of high strength, small flow loss, strong corrosion resistance, not easy to deform under long-term cold and hot conditions, and long service life.

The whole rolled fins are smooth, without burrs and wrinkles, easy to clean. It is easy to remove the condensed water on the outer surface of the fins when wet and cold in heating and air-conditioning projects, and it is not easy to form dust and scale in heat exchange places such as drying and heating.

How to do the daily maintenance of stainless steel finned tubes

1. Regularly check whether the cleaning of the stainless steel finned tubes is perfect, whether there are deposits, coking, scale and other scales attached, and clean them immediately.

At the same time, it is necessary to check whether each pipe is tightly bonded to the rubber pad and whether the rubber pad itself is intact to avoid leakage caused by degumming and damage to the rubber pad.

2. The compression nut and the upper and lower guide rods of the plate heat exchanger should always be lubricated with grease.

3. Special personnel shall be responsible for the adjustment of each instrument, and strictly implement the operating procedures for operation and maintenance.

4. When it is necessary to replace the rubber pad or repair the degummed part, the stainless steel finned tube should be taken out and placed on the table, or the glue residue in the tube groove should be wiped off with fine sandpaper at the degummed part, and then cleaned with carbon tetrachloride or trichloride.

Use a solvent such as vinyl chloride to wipe off the oil stains in the tank, and then use fine sandpaper to wipe off the back of the new rubber pad.

The oil stains should also be wiped off with a solvent such as carbon tetrachloride or trichlorethylene. Then, apply a thin coat of glue to the groove and the back of the rubber gasket. It doesn’t stick to fingers when it dries a bit, but it’s still sticky.

It is to insert the rubber pad into the groove, flatten it around, and then apply a layer of talcum powder. Then, install the stainless steel finned tubes on the equipment rack, clamping lightly.