Steam heat exchangers can completely replace a large amount of calorific value in steam to heat air. The heated air can be sent to various drying equipment. In modern industry, steam is a widely used ideal heat carrier.

1. The structure of the steam heat exchanger

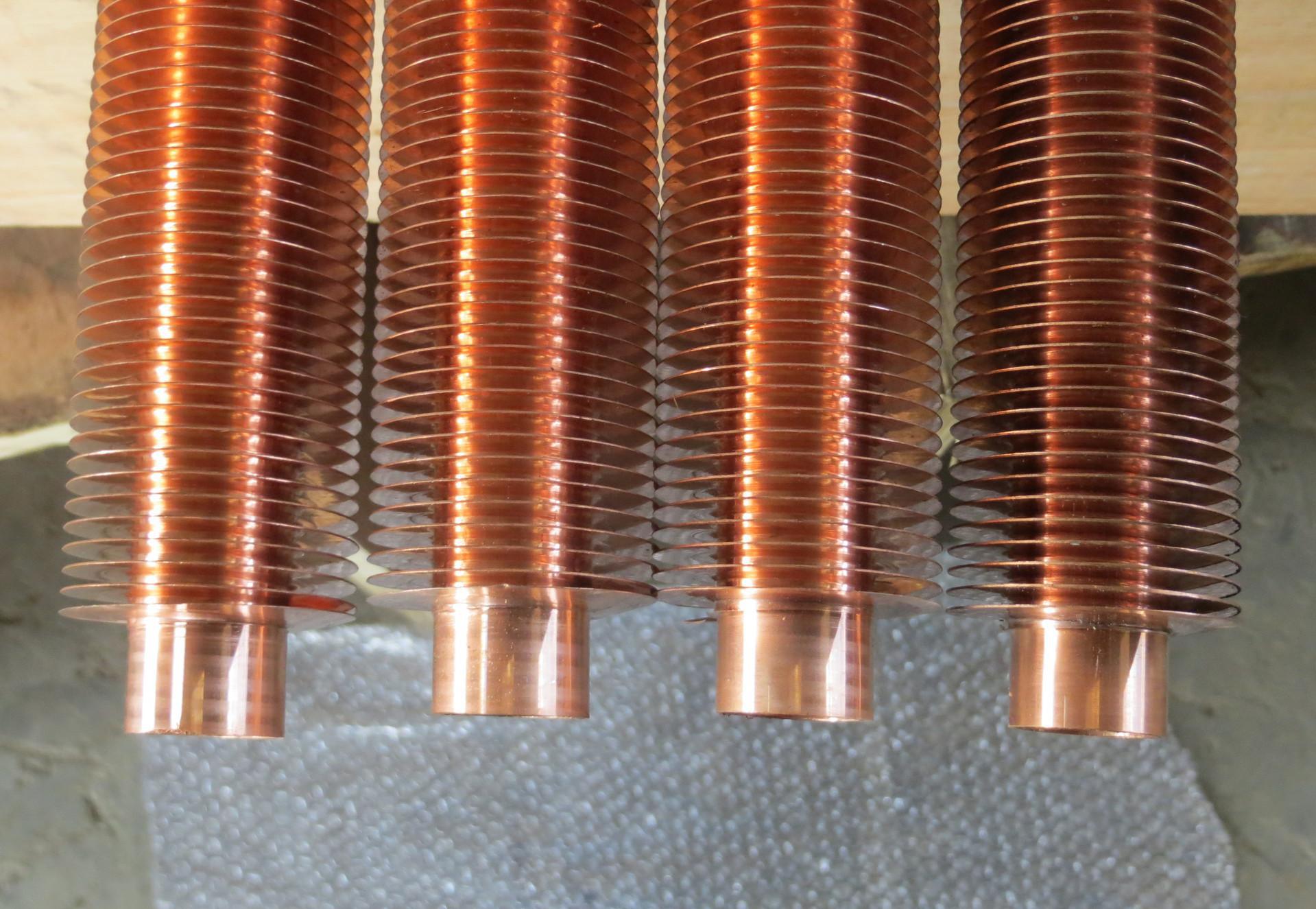

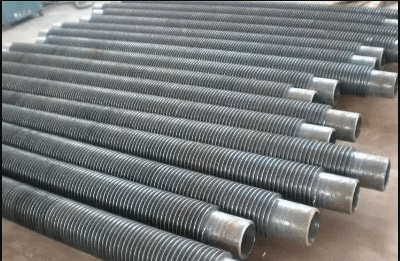

The steam heat exchanger uses steel-aluminum composite finned tubes as the main heat exchange element.

Due to the advanced composite technology, there is basically no contact thermal resistance below 210°C in the tube. Steam heaters combine the pressure resistance of steel pipes with the high thermal conductivity of aluminum for excellent heat transfer performance.

At the same time, the direct contact between the steel pipe and the air is avoided, which effectively improves the corrosion resistance.

Because the fins have no folds, the air resistance is lower than that of the wound type. At the same time, it has the advantages of easy cleaning, compact structure and large unit heat transfer area.

The steam heat exchanger belongs to the finned tube heat exchanger, and the heat transfer is enhanced by adding fins. Compact structure and high utilization rate.

Second, the working principle of the steam heat exchanger:

The steam entering the core is ejected at high speed along the side wall inclined toward the small hole, and its kinetic energy is absorbed by the water, pushing the water to flow along the tangential direction of the edge of the core, contacting the inner wall of the shell at a large angle, and being blocked by the shell from rotating. Due to the reasonable design of the shell solvent, the water flow speed is suitable and stable. The rotating water flow can not only better absorb steam kinetic energy and eliminate noise, but also disperse steam to form a large number of tiny soda units. This small combination produces low noise.

three. The main advantages of steam heat exchangers:

1. The thermal efficiency can reach 99%. The steam heat exchanger can evenly dissolve the steam in the water. Even if the pressure difference between the steam and the heated liquid is only 0.04Mpa, the steam can still be well added to the heated liquid, with small heat loss and high thermal efficiency.

2. High temperature of hot water: high temperature hot water can be obtained by using a vortex heater. The heating temperature is 98°C for an open container and 150°C for a pressure vessel. The working pressure of the steam heat exchanger is 1.6Mpa

3. Low vibration and noise: it is beneficial to improve the surrounding environment. Compared with the old flower tube heater, the eddy current muffler heater adopts the internal eddy current muffler structure, the noise is lower than 50db, and the vibration is also greatly reduced.

4. The total investment is low: the heat source steam directly enters the water tank, which can save the pump room equipment for hot water and save investment.

5. Simple operation and maintenance: water and steam are controlled separately, the remaining cold water in the water tank can be heated repeatedly, and the temperature control is convenient.

6. The steam heat exchanger is made of stainless steel, which has a long service life and does not need to be disassembled and maintained.