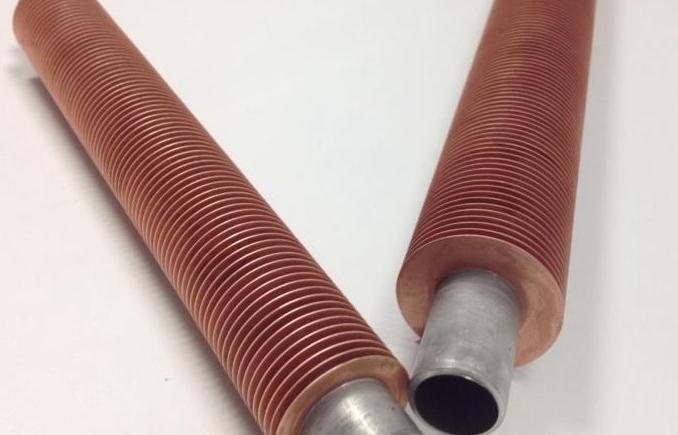

Finned tube radiator is the most widely used heat exchange equipment in gas and liquid heat exchangers. It achieves the purpose of enhancing heat transfer by adding fins to the common base tube.

The base pipe can be steel pipe; stainless steel pipe; copper pipe and so on. Fins can also use steel strips; stainless steel strips, copper strips, aluminum strips, etc.

The structural principle of finned tube radiators: All heat exchangers that add fins to the heat exchange tubes to increase the heat dissipation area can be summarized as “finned tube radiators”.

Finned tube radiators can be divided into winding fin type, series fin type, solder fin type and rolling fin type according to the fin structure. Commonly used materials are steel; stainless steel; copper; aluminum and so on.

The use of finned tube radiators: The most widely used finned radiators are steel-aluminum finned tubes (wrapped steel-aluminum composite finned tubes, rolled-sheet steel-aluminum composite finned tubes), which utilize The pressure resistance of the steel pipe and the high-efficiency thermal conductivity of aluminum are compounded on a special machine tool. Its thermal contact resistance is almost zero at 210°C.

Steel-aluminum composite tube radiators have irreplaceable advantages of other types of finned tube radiators.

Finned tube radiators are generally used for heating or cooling air, and have the characteristics of compact structure and large unit heat exchange area.

Widely used in textile, printing and dyeing, petroleum, chemical, drying, electric power and other fields.