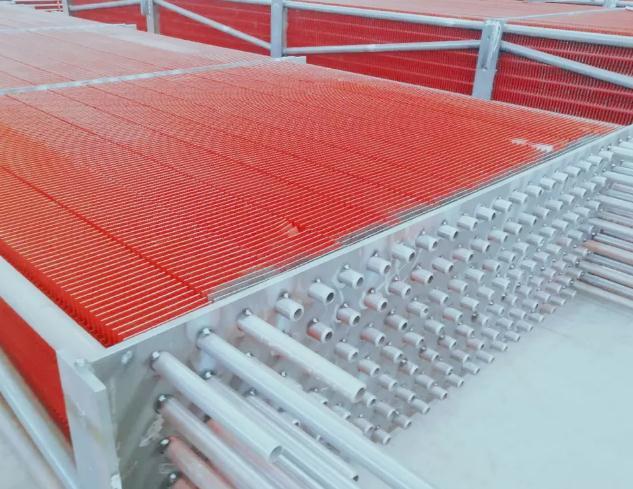

The key component of the economizer in the H type finned tube is the fins, and this type of fins can also be called butterfly tubes or booster tubes.

The combined economizer has high heat transfer Performance, so the application in different fields is relatively good, and the number of times of use is also very high, but due to its limited structure, there are many industries that cannot use this kind of H-shaped finned tube.

H type finned tubes can be mainly divided into two types in terms of structure, double H-type and H-type, because the structural expressions are different, and the industries and environments in which they are used are also different, but they are all based on the order.

For different arrangements, we still have to consider our own requirements first when choosing.

So what are the specific characteristics of the H type finned tube?

1. The economizer with H type finned tube can directly replace the economizer with bare tube, which not only improves the heat transfer area requirement, but also reduces the application of the number of finned tubes, and at the same time improves the overall flue gas flow rate.

The cross-section has a corresponding reduction in the flow velocity of the flue gas, mainly reducing the occurrence of wear and tear. Because there is a proportional problem between the number of times of wear between pipelines and the flue gas velocity, if the flue gas velocity decreases significantly, the wear rate will naturally decrease gradually.

After testing, it is concluded that the H-shaped finned tube itself has a concentrated The effect and function of the tube to discharge dust, so the finned tube has the effect of reducing the wear between the structures.

If the H type finned tube is made into a double H-shaped design, the rigidity will be improved higher, and it can be directly used as a long tube slot to use.

2. According to the application requirements, the economizers with H-shaped finned tubes are arranged in different orders.

The H-shaped radiator can allocate the space to different areas, which has a significant effect on the balance of the cyclone and reduces wear and tear. more obvious;

3. Because there are straight channels set on both sides of the H-shaped finned tube, the effect of ash discharge is relatively high;

4. The space design of the H type finned tube is relatively tight, so the overall weight is reduced a lot, and the manufacturing cost is also reduced;

5. Usually, the H-shaped finned tube has good energy-saving and consumption-reducing performance.

The power generation unit adopts the design method of economizer, which reduces the loss of exhaust gas by more than half, and the utilization rate of steam reaches about 3 kilowatts per ton;

6. H type finned tubes are particularly simple and labor-saving in daily maintenance and operation. The economizer uses an overall assembled manufacturing method with fewer moving parts.

The overall structural design is relatively simple and easy to install. Many, the automation effect of the design itself is remarkable, the operation and maintenance are more convenient, and the labor force of the staff is reduced.