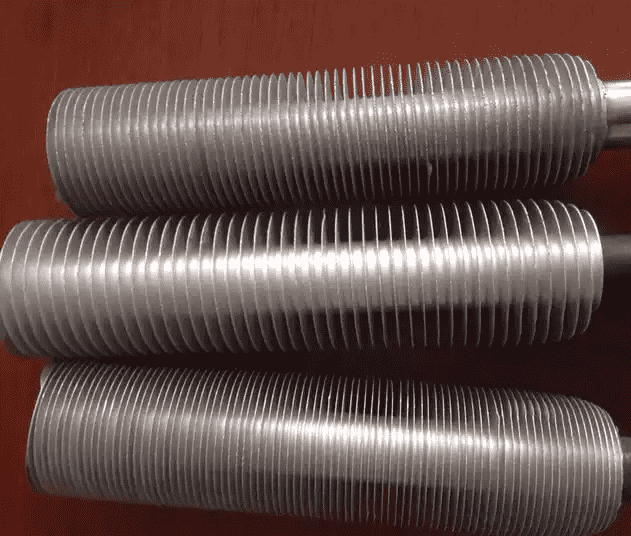

Extruded finned tubes are main devices for air coolers and the common application fields are:

� Heat exchangers for power plants ( electric, nuclear, thermal and geothermal power plants ).

� Steam condensate systems.

� Chemical and petrochemical industry.

� Food processing plants and refrigeration technology.

� Industrial ( steel mills, incinerators, gas compression facilities ).

Technical Specifications for Bimetal Extruded Finned Tubes:

| Tube Code | d | D | P | Fins per Inch |

Surface Area |

| mm | mm | mm | Nos. | Sq.m/m | |

| BM-16-37-2.8 | 16 | 37±1 | 2.80 | 9 | 0.62 |

| BM-16-37-2.5 | 2.54 | 10 | 0.69 | ||

| BM-16-37-2.3 | 2.30 | 11 | 0.76 | ||

| BM-19.05-42-2.8 | 19.05 | 42±1 | 2.80 | 9 | 0.78 |

| BM-19.05-42-2.5 | 2.54 | 10 | 0.86 | ||

| BM-19.05-42-2.3 | 2.30 | 11 | 0.95 | ||

| BM-22.22-54-3.6 | 22.22 | 54±1 | 3.62 | 7 | 1.05 |

| BM-22.22-54-3.1 | 3.17 | 8 | 1.19 | ||

| BM-22.22-54-2.8 | 2.80 | 9 | 1.35 | ||

| BM-22.22-54-2.5 | 2.54 | 10 | 1.50 | ||

| BM-22.22-54-2.3 | 2.30 | 11 | 1.65 | ||

| BM-25.4-57.15-3.6 | 25.4 | 57.15 (+0.8,-1.2) |

3.62 | 7 | 1.13 |

| BM-25.4-57.15-3.1 | 3.17 | 8 | 1.29 | ||

| BM-25.4-57.15-2.8 | 2.80 | 9 | 1.46 | ||

| BM-25.4-57.15-2.5 | 2.54 | 10 | 1.62 | ||

| BM-25.4-57.15-2.3 | 2.30 | 11 | 1.78 | ||

| BM-31.75-63.5-3.6 | 31.75 | 63.5 (+0.8,-1.2) |

3.62 | 7 | 1.30 |

| BM-31.75-63.5-3.1 | 3.17 | 8 | 1.49 | ||

| BM-31.75-63.5-2.8 | 2.80 | 9 | 1.68 | ||

| BM-31.75-63.5-2.5 | 2.54 | 10 | 1.86 | ||

| BM-31.75-63.5-2.3 | 2.30 | 11 | 2.05 | ||

| BM-38.1-69.85-3.6 | 38.1 | 69.85 (+0.8,-1.2) |

3.62 | 7 | 1.48 |

| BM-38.1-69.85-3.1 | 3.17 | 8 | 1.69 | ||

| BM-38.1-69.85-2.8 | 2.80 | 9 | 1.91 | ||

| BM-38.1-69.85-2.5 | 2.54 | 10 | 2.12 | ||

| BM-38.1-69.85-2.3 | 2.30 | 11 | 2.33 | ||

| BM : Bimetalic Extruded Finned Tubes | |||||

| d : Base tube diameter | |||||

| D : Fin Outer diameter | |||||

| P : Fin pitch | |||||

Technical Specifications for Monometalic Extruded Finned Tubes:

| Tube Code | D | d | dw | P | Fins per Inch |

| mm | mm | mm | mm | Nos. | |

| MM-38-20-16-2.8 | 38 | 20 | 16 | 2.80 | 9 |

| MM-38-20-16-2.5 | 2.54 | 10 | |||

| MM-38-20-16-2.3 | 2.30 | 11 | |||

| MM-51-29-25-3.6 | 51 | 29 | 25 | 3.62 | 7 |

| MM-51-29-25-3.1 | 3.17 | 8 | |||

| MM-51-29-25-2.8 | 2.80 | 9 | |||

| MM-51-29-25-2.5 | 2.54 | 10 | |||

| MM-51-29-25-2.3 | 2.30 | 11 | |||

| MM-57-33-29-3.6 | 57 | 33 | 29 | 3.62 | 7 |

| MM-57-33-29-3.1 | 3.17 | 8 | |||

| MM-57-33-29-2.8 | 2.80 | 9 | |||

| MM-57-33-29-2.5 | 2.54 | 10 | |||

| MM-57-33-29-2.3 | 2.30 | 11 | |||

| MM : Monometalic Extruded Finned Tubes | |||||

| D : Fin outer diameter | |||||

| d : Root diameter | |||||

| dw : Tube ID | |||||

| P : Fin pitch | |||||

Tension wound finned tubes, embedded finned tubes and extruded finned tubes are main devices for air coolers and the common application fields are:

Heat exchangers for power plants (electric, nuclear, thermal and geothermal power plants)

Steam condensate systems

Chemical and petrochemical industry

Food processing plants and refrigeration technology

Industrial (steel mills, incinerators, gas compression facilities).