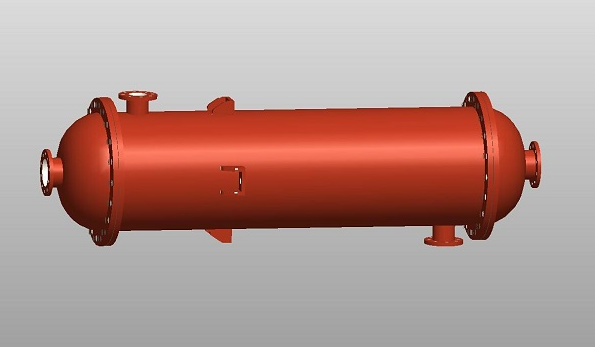

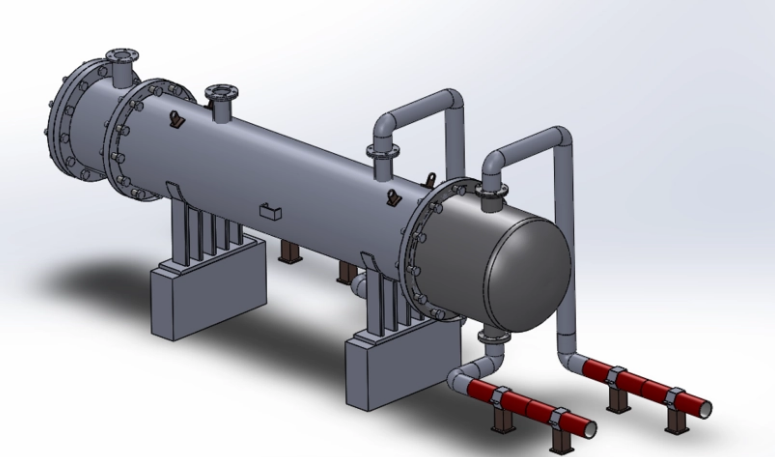

The tubular heat exchanger is composed of a shell, a heat transfer tube bundle, a tube plate, a baffle (baffle) and a tube box. The shell is generally cylindrical, and the heat transfer tube bundle is installed inside. on the tube sheet.

The fluid for heat exchange is divided into two types: cold and hot, which are called tube-side fluid and shell-side fluid according to their flow positions.

In order to improve the heat transfer coefficient of the shell-side fluid, generally a number of baffles are installed in the shell, and at the same time, the velocity of the shell-side fluid is increased, and the fluid turbulence is enhanced by passing through the tube bundle multiple times.

Material of tube heat exchanger:

Metal material: stainless steel, common brass, industrial pure copper

Non-metallic materials: ceramics, glass, PTFE, graphite

Thermal conductivity coefficient: non-metal <stainless steel <common brass <industrial pure copper

Advantages of shell and tube heat exchangers:

1. High heat transfer coefficient:

The threaded tube is a high-efficiency heat transfer element combined with internal and external threads made of copper or stainless steel with high thermal conductivity.

The threaded tube heat exchanger made of it can withstand low fluid resistance. , it forms a strong turbulent flow, which greatly improves the heat release coefficient inside and outside the tube.

After testing, the total heat transfer coefficient of steam-water heat exchange reaches 3000~6000W/m2℃, and the total heat transfer coefficient of water-water heat exchange reaches 2500~5500W /m2℃.

2. Compact structure:

This product has a large heat transfer area per unit volume. The total heat transfer coefficient is high, so the occupied area is greatly reduced, saving materials and space.

3. Not easy to scale:

Due to the special concave-convex structure of the threaded pipe, there are multiple flow layers and rotating scours inside and outside the pipe.

In addition to the heat expansion and contraction of the pipe, there will be no impurities inside and outside the pipe wall, so it is not easy to scale. , the long-term operation effect is good.

4. Not easy to leak:

The sealing circumference of this product is short, and the thick thread of the threaded pipe is similar to an expansion joint, which has its own compensation ability, and the thermal stress of the heat exchanger is small, so it is not easy to leak.

5. Easy installation:

This series of heat exchangers has two types, horizontal and vertical, which are easy to install in different positions.

6. Compulsory supervisory inspection, reliable quality:

In strict accordance with GB150-1998 “Steel Pressure Vessel”, GB151-1999 “Shell and Tube Heat Exchanger” and related standards for manufacturing, inspection and acceptance, and accept “Supervision Regulations on Safety Technology of Pressure Vessels” supervision.