Working principle of finned tube radiator

● Why add fins?

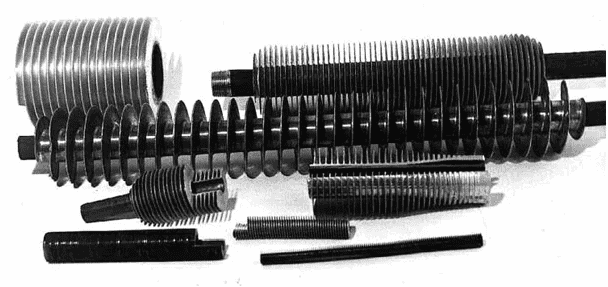

Finned tube radiator is a kind of heat exchange equipment used in industry to heat or cool air. Since the heat transfer coefficient of air is relatively low and the heat transfer coefficient of the medium inside the tube is high, the difference between the two is relatively large, so fins are processed outside the tube to achieve the purpose of enhancing heat transfer.

● What are the requirements for materials?

The base tubes of finned tube radiator are generally carbon steel tubes, stainless steel tubes, and copper tubes. The material of the fins is aluminum, stainless steel, carbon steel, copper, etc. Among them, the rolled finned tube material can only be made of aluminum, and the commonly used aluminum tube material is A1060/A1070.

Steel-aluminum composite finned tube radiators What are the characteristics of steel-aluminum composite finned tube radiators?

Steel-aluminum composite finned tube radiator are widely used, mainly because of their wide application range. Whether it is for heating or cooling air, the temperature range of air can be from -30°C to 250°C. Contact thermal resistance is almost zero.

At the same time, it utilizes the pressure resistance performance of the steel pipe and the high-efficiency heat transfer performance of the aluminum material. The advantages of the two are combined, the heat transfer performance is excellent, the temperature is resistant to sudden changes, it is easy to clean, and it is not easy to scale and ash.

● What are the applications of finned tube radiator?

In industry, there will be applications wherever heating or cooling air is required. In textile printing and dyeing, chemical metallurgy, drying equipment, and other process control fields.