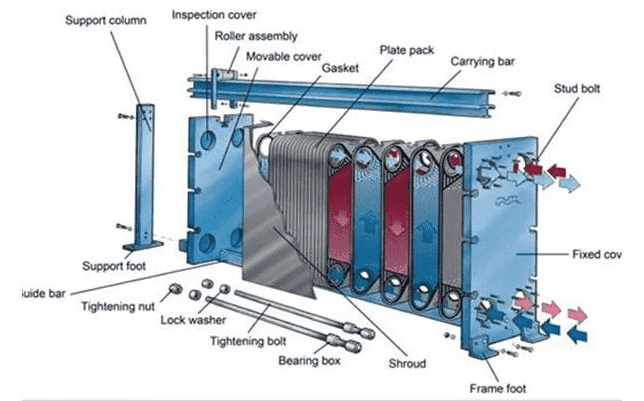

Plate-fin heat exchangers usually have three major parts, one is the plate bundle, the other is the choke, and the third is the shell.

Many people are not very clear about the detailed subdivision of parts, let alone the raw materials of these parts. Today, we will mainly talk about these parts and raw materials.

Generally speaking, the plate-fin heat exchanger is mainly composed of the plate pack welded by the plates, the cylinder cylinder, the connection, the flanges, the bolts, and the welding material.

The main materials of the plate bundle are SUS304L, SUS316L, AISI 904, Titanium, Hastelloy, SMO254, Nickel. As the core heat exchange element of the plate-fin heat exchanger, the plate bundle has the most available materials. Different working conditions require different materials.

The main materials of the cylinder are Q345R and SUS304. Q345R is characterized by wear resistance, high temperature resistance, corrosion resistance, high strength and yield, and is widely used.

The main materials of the connection are 20 carbon steel, SUS304 and SUS316L. No. 20 carbon steel has better weldability and toughness.

The main materials of the flange are Q235B, No. 20 carbon steel and SUS304. Q235B carbon steel has moderate carbon content, good overall performance, and is widely used.

The main materials of bolts are No. 45 steel, 40Cr, 35CrMoA and SUS304 etc.

The main materials of welding consumables are J422, J507 and ER308.