Aluminum Finned Tubes for Air Cooled Heat Exchanger

How is it handled, generally? Simply put, in terms of aluminum fins, it refers to adding metal sheets with strong thermal conductivity to the heat exchange device to make them larger, thereby increasing the heat transfer coefficient and improving the heat transfer effect.

In this way, the metal sheet with the above functions is called a fin. If the metal used is aluminum, it is an aluminum sheet. The processing method of aluminum fins depends on its specific application.

It can be processed by a forming machine in the radiator. The process characteristics of the aluminum extruded finned tube are: because the extruded aluminum finned tube is in the form of an aluminum tube sleeved with an aluminum tube, the base tube can be made of carbon steel pipe, copper pipe or stainless steel pipe.

Also, the aluminum tube is extruded. In this way, its base and the outer wall of the tube can be closely fitted, so as to obtain a high heat transfer coefficient and good heat transfer performance.

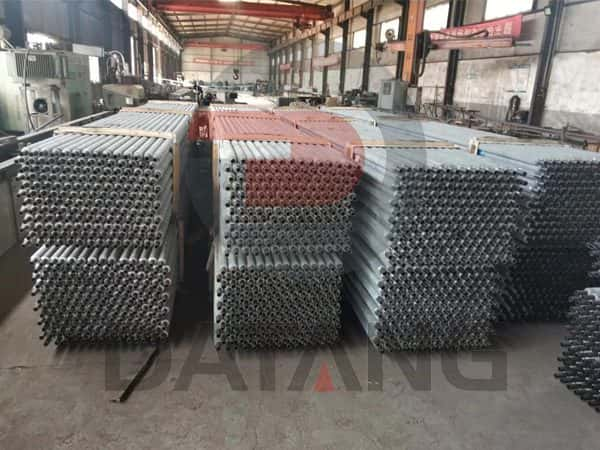

Aluminum Finned Tube

The surface of the aluminum finned tube is smooth, free of defects such as burrs and wrinkles, and it is easy to clean and will not accumulate dust and scale, so it can be used well and fully utilized.

Plus, its surface is anodized to prevent it from corroding. Technically, the overall rolling processing method can achieve non-contact thermal resistance, and has the characteristics of high strength and resistance to mechanical vibration. In addition, it has better thermal expansion.

Therefore, when it is used in a heat exchanger, the heat exchange effect is very good. Compared with the type of aluminum sheet tube, its base tube is more commonly made of stainless steel, carbon steel and copper and other raw materials.

After being kneaded and formed by professional equipment, the finned tube we need is made. The azimuth direction of the tube at the base must be more closely fitted with the outer wall of the tube, which is a prominent advantage of the aluminum fin tube.

Aluminum Finned Tubes

Moreover, the heat transfer coefficient of the aluminum finned tube is appropriately improved, and the heat transfer effect is also relatively good, mainly because its surface does not have any burrs and wrinkles, the overall appearance is very bright and beautiful, and it is also relatively fast in cleaning, mainly using The heater, or condenser housing, is used to drain the condensate.

If the aluminum finned tube is used for drying and heating, there will definitely not be bad phenomena such as scaling and dusting, because the aluminum finned tube first presents a trapezoid in the cross section, so it mainly presents as a cross section.

Trapezoid, therefore, its strength will be higher, and there will be no undesirable phenomena such as scaling and dusting. Aluminum alloy radiators are basically made of aluminum tubes, or rolled with copper tubes and iron tubes, so their thermal resistance is small, and they have high heat transfer performance, and the anti-corrosion function is also very powerful, the most important thing.

However, the movement loss is relatively small, and even if it is processed under the condition of uneven heating and cooling for a long time, it does not show deformation.