How to choose steel-aluminum bimetallic extruded finned tubes?

Tube Material:Carbon Steel,Stainless Steel,Alloy Steel, Aluminum,Copper

When purchasing steel-aluminum bimetallic extruded fin tubes, priority should be given to the material, finned tube length, fin spacing and surface treatment method.

Material selection: High-quality stainless steel, such as 304 or 316, should be given priority to increase the corrosion resistance and service life of the finned tube.

Finned tube length: According to actual use needs, choose the appropriate length to improve heat exchange efficiency.

Fin spacing: The distance between the fins should be appropriate to reduce fluid resistance and improve heat transfer effect.

Surface treatment: Considering corrosion resistance and aesthetics, surface treatment methods such as galvanizing or plastic spraying can be selected.

In addition, the installation environment, usage requirements and maintenance costs are also factors that need to be considered when choosing steel-aluminum finned tube radiators.

For humid and highly corrosive environments, it is necessary to choose a radiator with superior anti-corrosion performance, such as a steel-aluminum finned tube radiator with special coating treatment.

At the same time, the size and shape of the installation space will also limit the size and shape of the radiator, so it is necessary to customize it according to the specific situation when choosing.

For radiators that need to adjust the temperature frequently or run for a long time, its durability and stability must also be considered.

Finally, choose products with reliable quality and excellent service to reduce the subsequent maintenance costs.

Steel-aluminum bimetallic extruded finned tube is an efficient and energy-saving heat transfer element, which is widely used in various industrial fields.

Steel-aluminum bimetallic extruded finned tube is composed of two materials, steel and aluminum, and is manufactured through a precise extrusion process. This compact heat transfer element has excellent corrosion resistance and high mechanical strength, which can effectively reduce energy consumption and improve the operating efficiency of the equipment. Its features include:

Excellent corrosion resistance: Since the outer surface of the finned tube is covered with a layer of metal material, this layer of material can effectively resist various chemical corrosion and oxidation, ensuring the service life of the finned tube.

Higher mechanical strength: Due to the optimization of material selection and manufacturing process, the mechanical strength of finned tubes has been significantly improved, and they can withstand greater pressure and vibration, ensuring the stable operation of the equipment.

Wide application fields: It can be used as a heat transfer element in various thermal equipment, such as boilers, dryers, reactors, etc., and can also be used as a radiator, such as computer radiators, car radiators, etc.

High-efficiency heat exchange performance: The design of the fins can increase the heat exchange area and improve the heat exchange efficiency. The high-frequency welding process ensures the close connection between the fins and the base tube, avoiding the generation of thermal resistance.

Excellent corrosion resistance: Both steel and aluminum have good corrosion resistance, can resist various chemical corrosion and electrochemical corrosion, and are suitable for various harsh working environments.

In short, as a high-performance heat dissipation device, steel-aluminum bimetallic extruded finned tubes have broad application prospects.

However, strict quality control is required during the manufacturing process, and regular inspection and maintenance are required during use to ensure its long-term stable operation and efficient heat transfer.

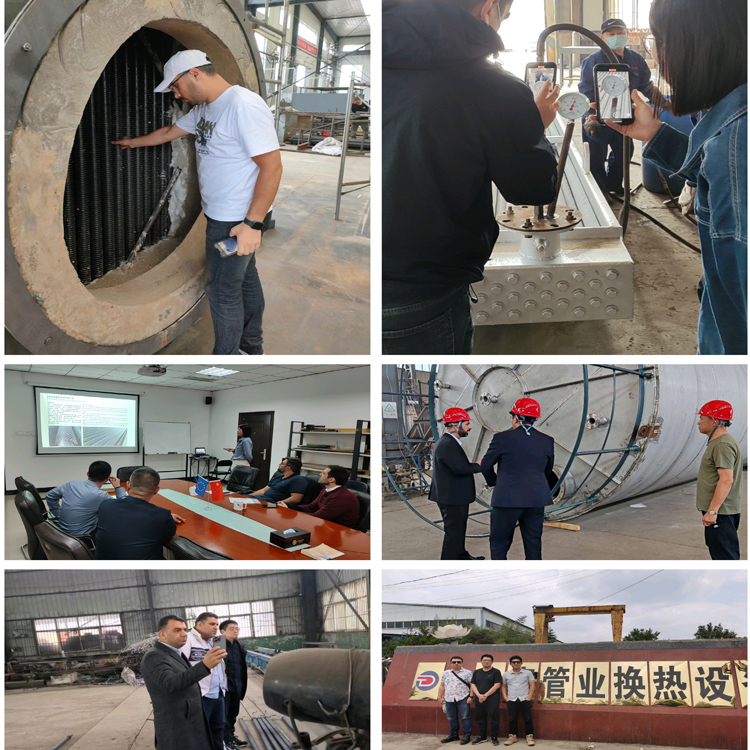

Inspection&Packing

Factory Photos

Customer factory inspection

Contact Us

Company name: Cangzhou Datang Steel Pipe Co., Ltd

Address: Cangzhou City, Hebei Province, China

Contacts: Sunny Yang

Whatsapp Number: +86 15690122018

Email: datangfintube@gmail.com