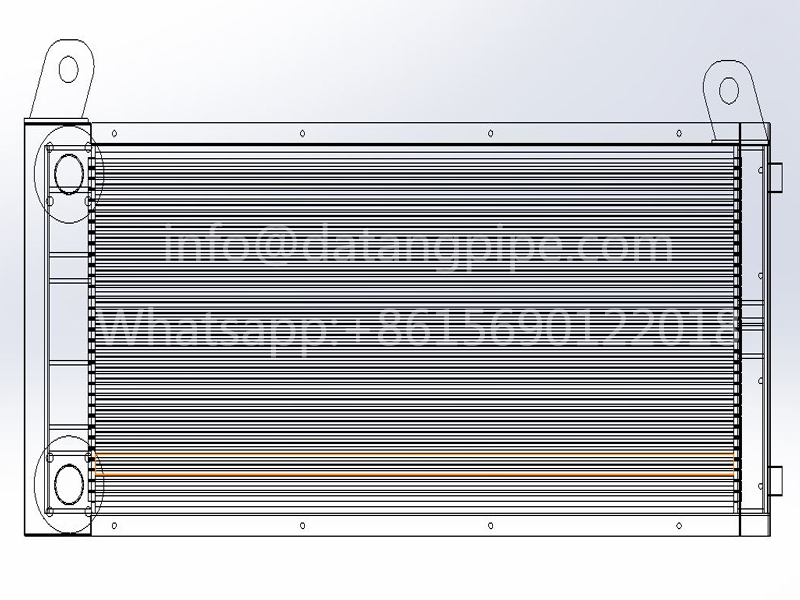

Extruded aluminum finned tube heat exchanger for drying industry

Extruded aluminum finned tube heat exchanger is mainly used for drying materials of various materials.

Extruded aluminum finned tube heat exchanger is a high-efficiency heat exchange equipment, which is widely used in drying operations.

The internal space size of the drying room or dryer equipment and the hot air temperature standard during the drying operation are used to determine the heat exchange area and heat dissipation speed of the finned tube industrial radiator installed and used.

It is necessary to determine the specific material and diameter of the spiral finned tube set in the internal structure in combination with the material type of the material being dried. The internal base tube of the spiral finned tube is generally defaulted to the national standard seamless steel pipe, which can meet the pipeline heating system with steam or heat transfer oil as the medium. To ensure that the overall dryer equipment or drying room can obtain the corresponding drying effect, it is necessary to meet the internal heat demand of the overall space.

This heat exchanger increases the air contact area of the internal medium during the heat dissipation process by compounding spiral heat dissipation fins on the surface of the original smooth steel pipe, thereby accelerating the heat transfer speed. The material type of the heat dissipation fins on its surface has a direct impact on the heat dissipation rate of the medium. Therefore, choosing the right fin material is crucial to improving the drying efficiency.

In the application of the dryer, the extruded aluminum fin tube heat exchanger can meet specific heat exchange requirements and can also adapt to various performance requirements and condition restrictions in the application environment.

According to the internal space size of the drying room or dryer equipment and the hot air temperature standard during the drying operation, the heat exchange area and heat dissipation rate of the finned tube industrial radiator installed and used can be determined.

The material type of the material being dried is also one of the important factors that determine the specific material and diameter size of the spiral fin tube in the internal structure.

The use of extruded aluminum fin tube heat exchangers not only improves the drying efficiency, but also because of its good corrosion resistance, it is particularly suitable for use in food material drying operations, ensuring a more stable heat dissipation effect during the specific heat exchange application process.

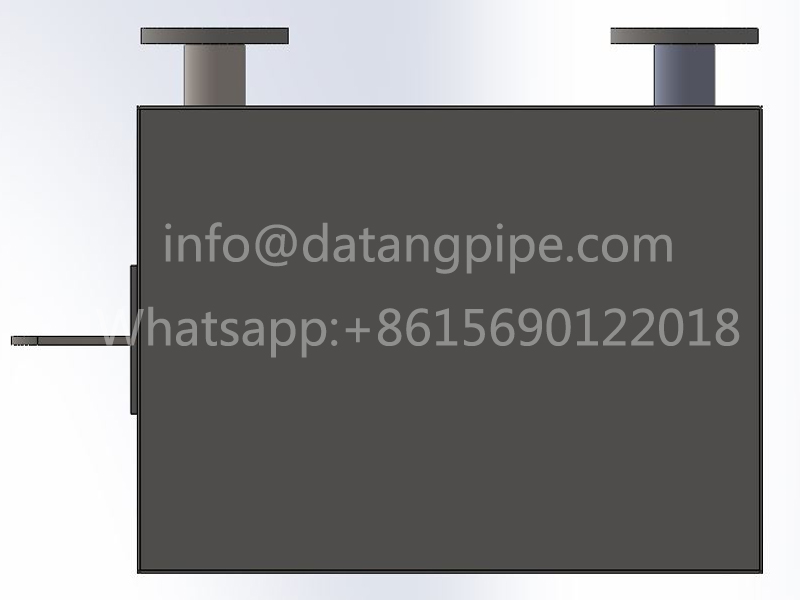

Finned Tube Air Cooled Heat Exchangers

Contact Us:datangfintube@gmail.com

Contact Us:datangfintube@gmail.com

Blow type air cooler Industrial cooling equipment

Contact Us:datangfintube@gmail.com

Stainless steel high-frequency welded finned tube heat exchanger

Contact Us:datangfintube@gmail.com