Finned Tube For heat exchange

Over 15 years experience

Out standing quality

Three different finning process

Different coiling and bending process

Contact Us:datangfintube@gmail.com

About Finned Tubes

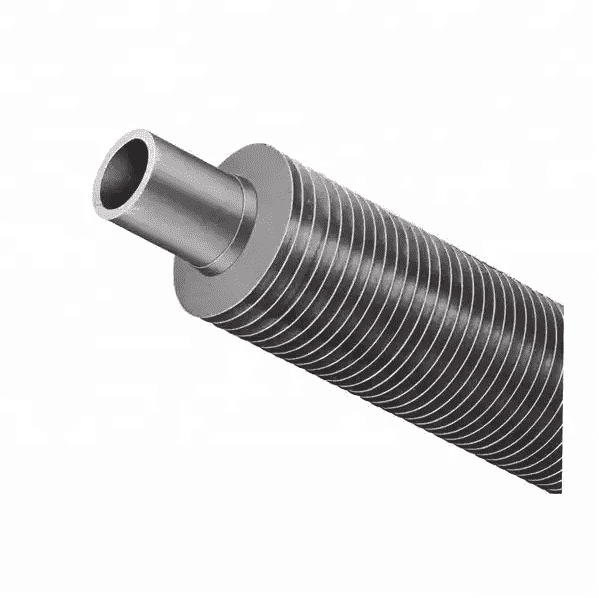

With an aim to increase the heat exchanging efficiency, It’s usually to extend the surface area (or internal surface area) by adding fins onto a tube, which, through this manufacturing process, would greatly improve and upgrade the heat transferring efficiency of heating tube, it’s called Finned Tube or Fin Tubes.

♦ Welded finned tubes

♦ Extruded finned tubes

♦ Welded helical solid finned tubes

♦ Welded serrated finned tubes

♦ Welded helical serrated finned tubes

Items | Code | Dimensions | Tolerances |

Tube outside diameter | D1 | Φ25~Φ219 mm | ±0.2 mm |

Fin outside diameter | D2 | Φ37~Φ279 mm | ±0.75 mm |

Fin pitch | M | 4~90 mm | ±0.2 mm |

Fin height | H | 6~30 mm | ±0.75 mm |

Tube thickness | δ1 | 2~16 mm | ±0.15 mm |

Fin thickness | δ2 | 0.8~2.5 mm | ±0.1 mm |

Unfinned tube ends length | L1 | customized | ±1‰*L1 mm |

Unfinned tube ends length | L2 | customized | ±1‰*L2 mm |

Maximum tube length | L | 0.5~25 m | ±1‰*L mm |