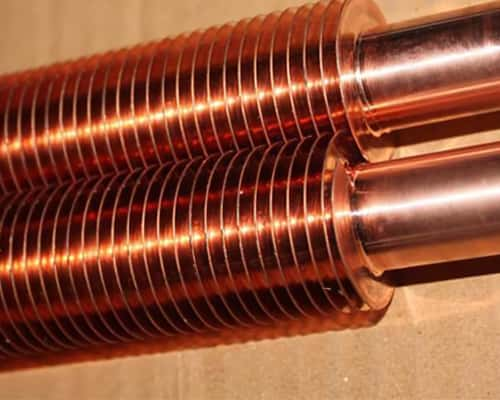

SG-Extruded Fin (Bi-metallic Fin)

Application: High-efficiency Extruded Finned Tube for higher temperature applications giving complete and permanent atmospheric corrosion protection of the base tube. Using over 40% more aluminium than the equivalent applied fin, the extended fin is very robust and resistant to mechanical damage, allowing the Extruded Finned Tube to be cleaned without damage using either steam or high-pressure water

Upper limiting temperature: 300°C

Manufacture: A carefully degreased core tube is fitted into an aluminium primary tube. This assembly is then fed into the triple-spindle finning head

of the fin-extruding machine. Three special multi-disc packs extrude the aluminium tube into helical high fins while reducing the inner diameter to give firm pressure contact with the core tube

Fin materials: Aluminium

Base tube materials: Any metallic material

STANDARD DIMENSIONS OF EXTRUDED FIN TUBES

Base tube dia. (mm): 25.0, 25.4, 31.8, 38.1

Fin height (mm): 15.88

Fin pitch: 354, 393, 433 fins/metre

The finned tube provide by us is Extruded Type, which is different from the ones through HF Welding and Wrapping method. Based on this structure, the Extruded type can survive more severe working conditions than other finned tubes. Also it, on the other hand, shows several unique features such as enhanced physical structure, resistance to vibration, anti-corrosion ability, and long service life, etc.

Extruded Finned Tube gives very good corrosion protection to the base tube, as the base tube is not visible to the atmosphere in between the fins.

Aluminum Extruded Finned Tube refers to a kind of heat exchange device. To improve the heat exchange efficiency, fins are usually added to the surface of the core tube to increase the outer surface area (or inner surface area).

The aluminium finned tube is a new, wear-resistant and efficient heat exchange material. It is a high-efficiency and energy-saving heat exchange element, which has the characteristics of high heat exchange efficiency, large heat dissipation area, long service life, wide temperature range and high-pressure adaption.

Aluminum Extruded Finned Tube are typically used in higher temperature applications.

Air cooler, processing cooling, lube oil cooling

Heat exchanger, steam air heater

Economizer

Gas compressor

Waste incinerator

Blast furnace/ rotating furnace, etc

Tube material: carbon steel ; stainless steel; copper

Fin Material: Aluminum

Upper temperature limit: 350°C

Extruded Bimetallic Finned Tubes

Extruded Finned Tube is composite with iron-aluminum or copper-aluminum tube rolling out the fin, which feathers are tightness, small heat resistance, good heat transfer performance, high strength, small flow losses, strong corrosion resistant performance, not easy to deformation and a long working lifetime in cold and hot condition, etc.

Overall rolling fin is smooth and has no burr, so it is easy to clean. It is easy to make the fin surface wet and cooled with water when makes it cold during heating air-conditioning engineering. In the situation with drying, heating and other heat exchanging, its surface is handles by anodizing, which with beautiful color and luster, and can effectively prevent surface corrosion.

Aluminum rolling finned tube is rolling as a whole by the aluminum tube, which has the feather that no contact thermal resistance, high strength, thermal shock and mechanical shock, good thermal performance, and considerable expansion heat transfer surface. The heat ex-changer with this kind of finned tube is ahead of the string or around the plate ones.